The Ultimate Guide to Remanufactured Short Block Engines and Short Block Engine Replacement

Dive deeply into the world of remanufactured short block engines, why they are a reliable option, and how short block engine replacement can save you time and money.

When your engine gives out, it can seem like the end of your car’s life. However, there are options available beyond buying a new engine or vehicle. Two major options are remanufactured short block engines and short block engine replacement services. These solutions offer a second life to your vehicle, often at a fraction of the cost of a brand-new engine. If you're ready to bring your vehicle back to life, there are many high-quality short blocks for sale from reputable remanufacturers that can match your engine's original performance — or even surpass it.

In this guide, we'll dive deeply into the world of remanufactured short block engines, why they are a reliable option, and how short block engine replacement can save you time and money.

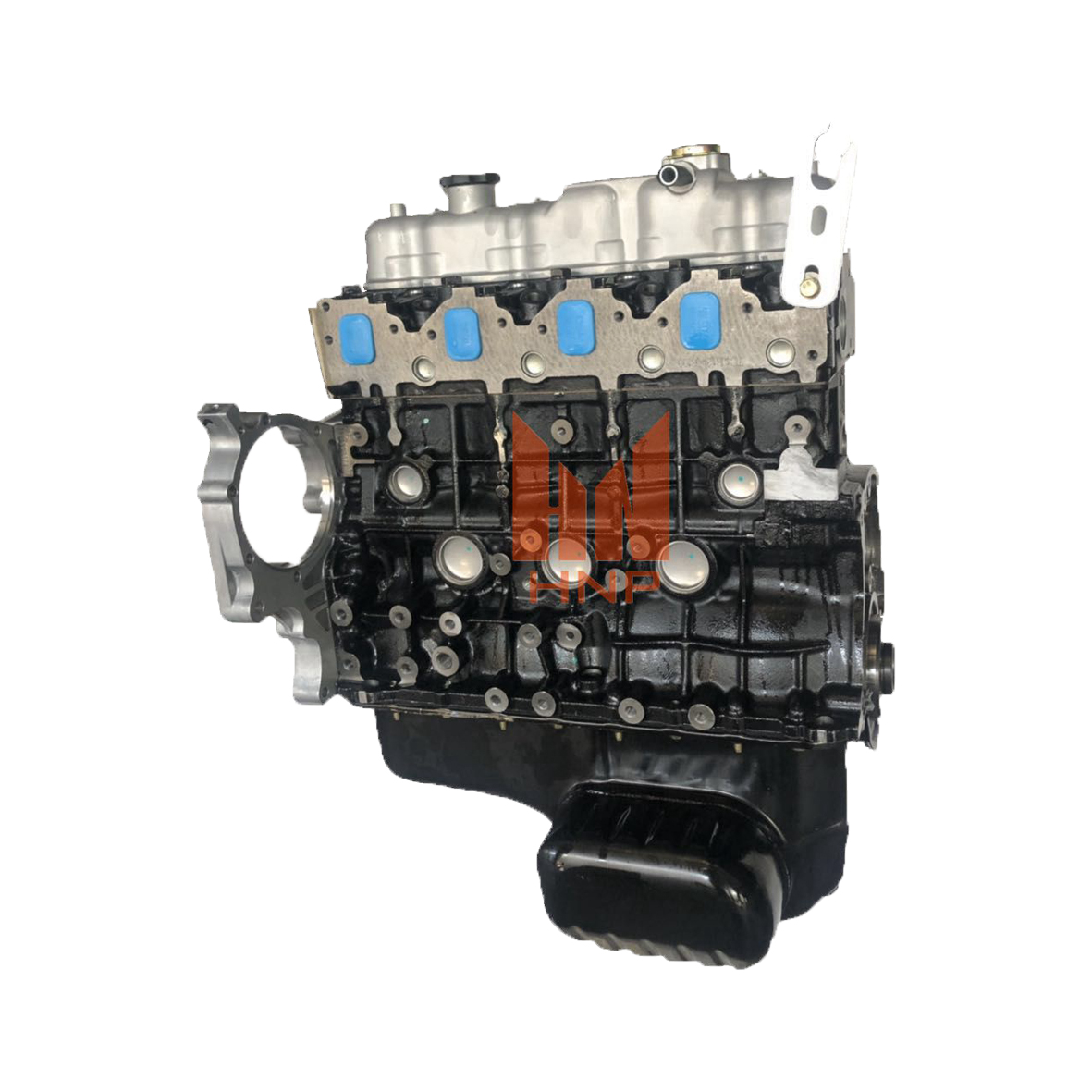

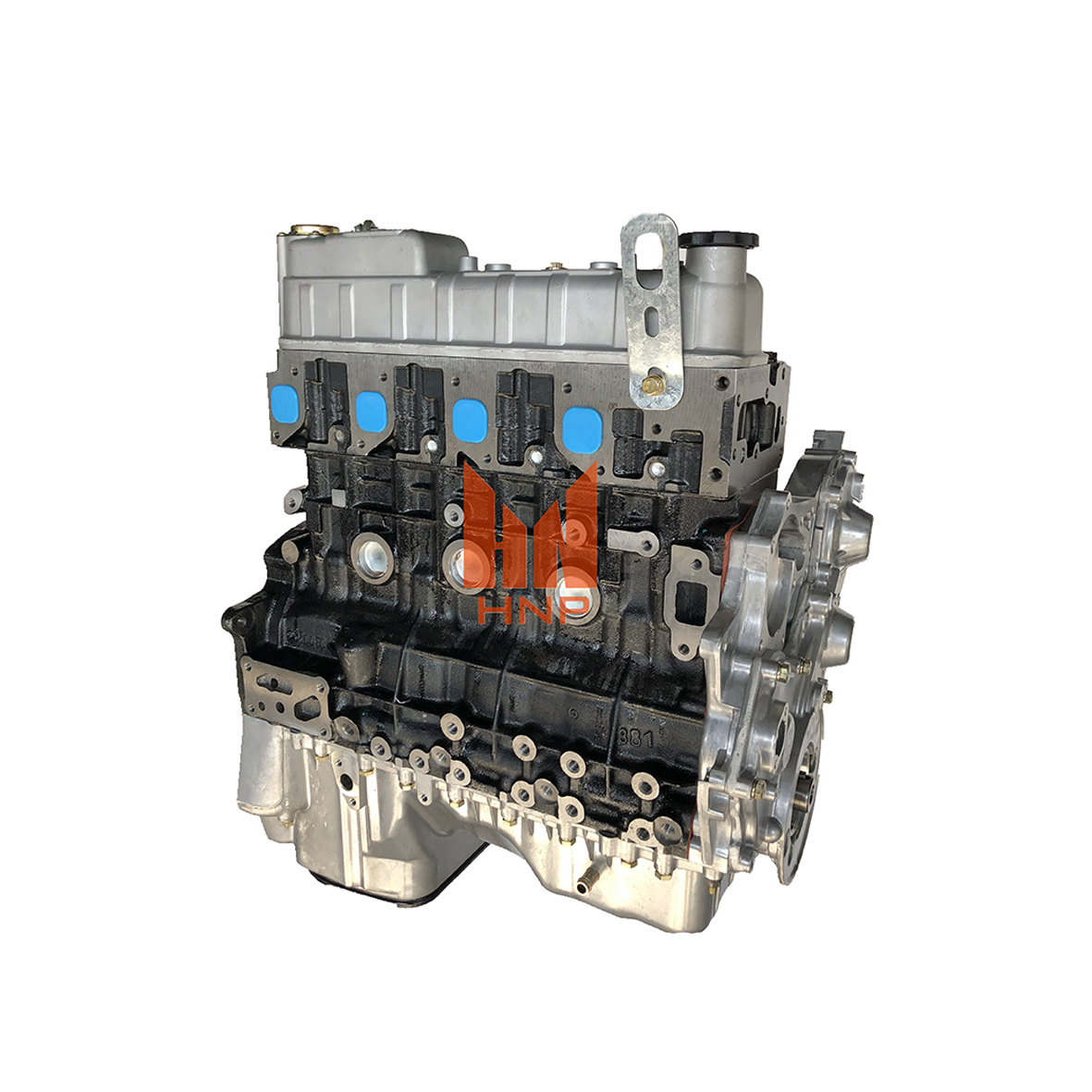

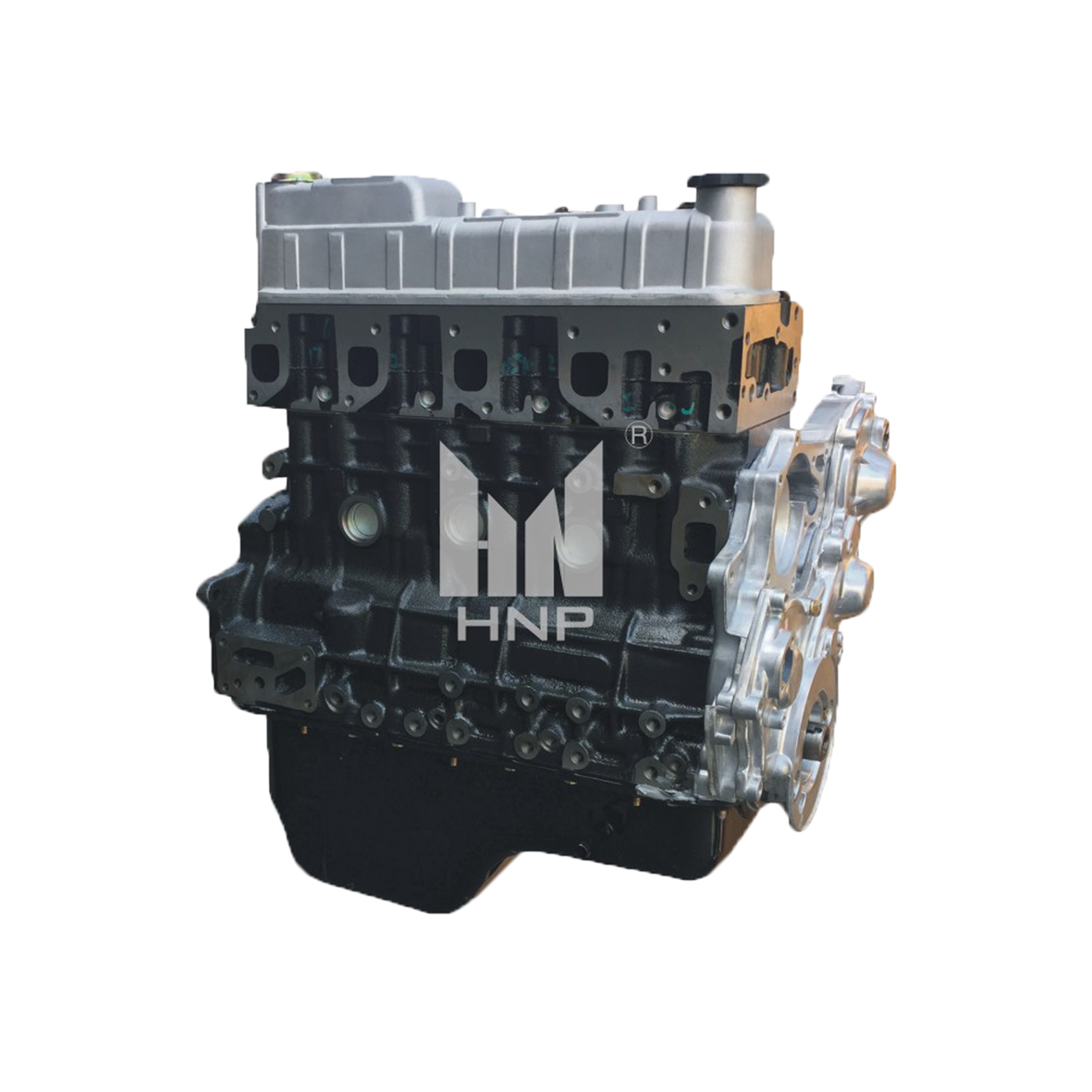

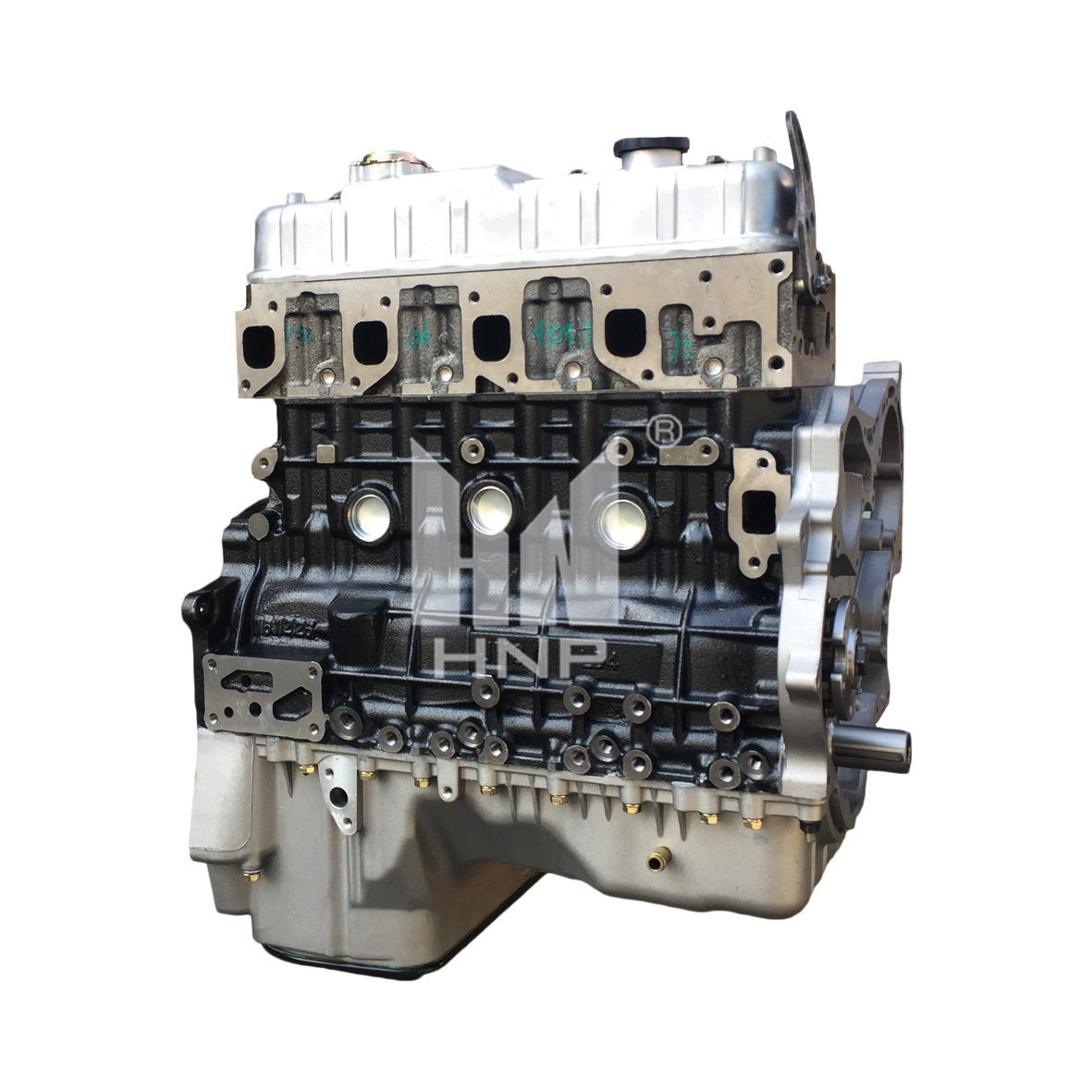

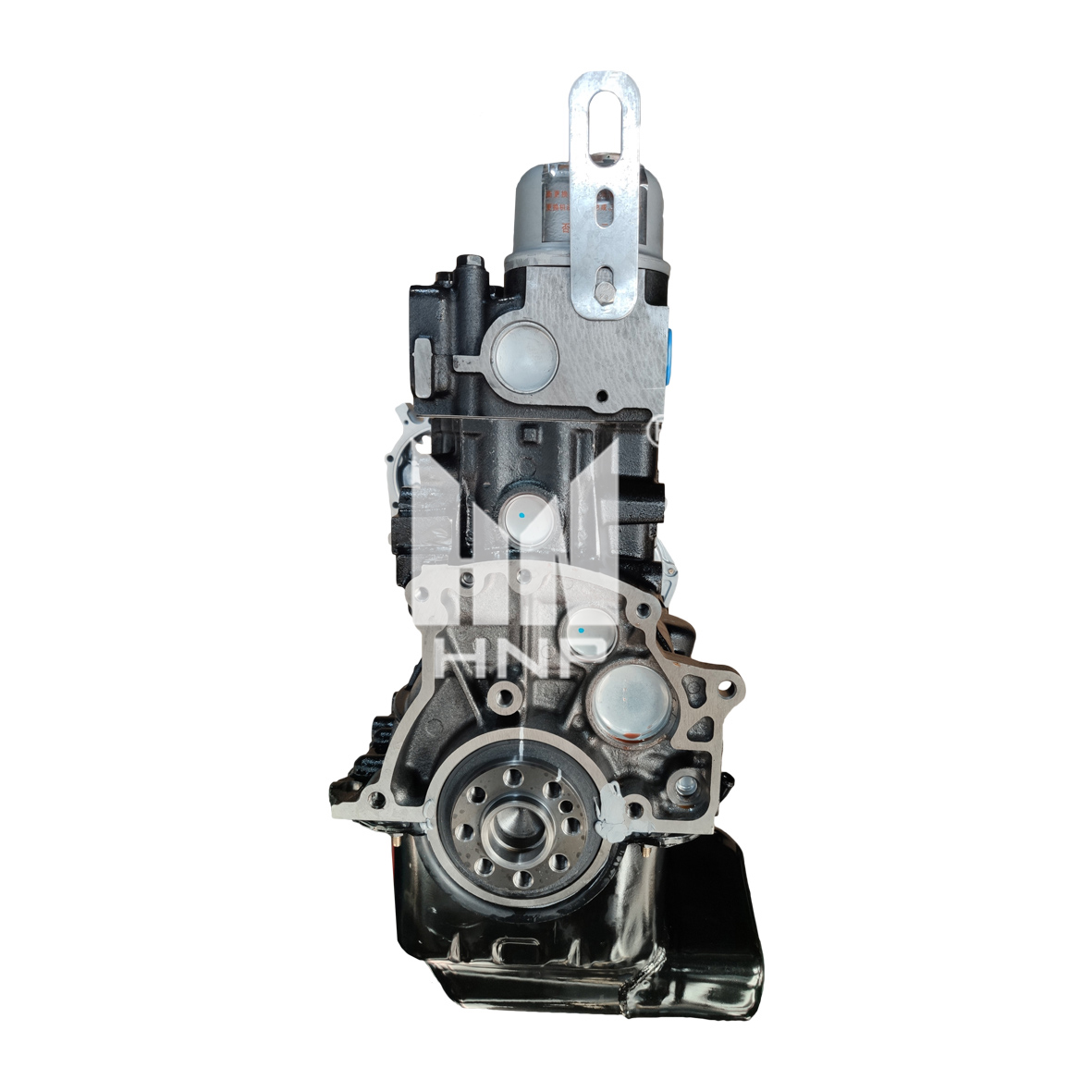

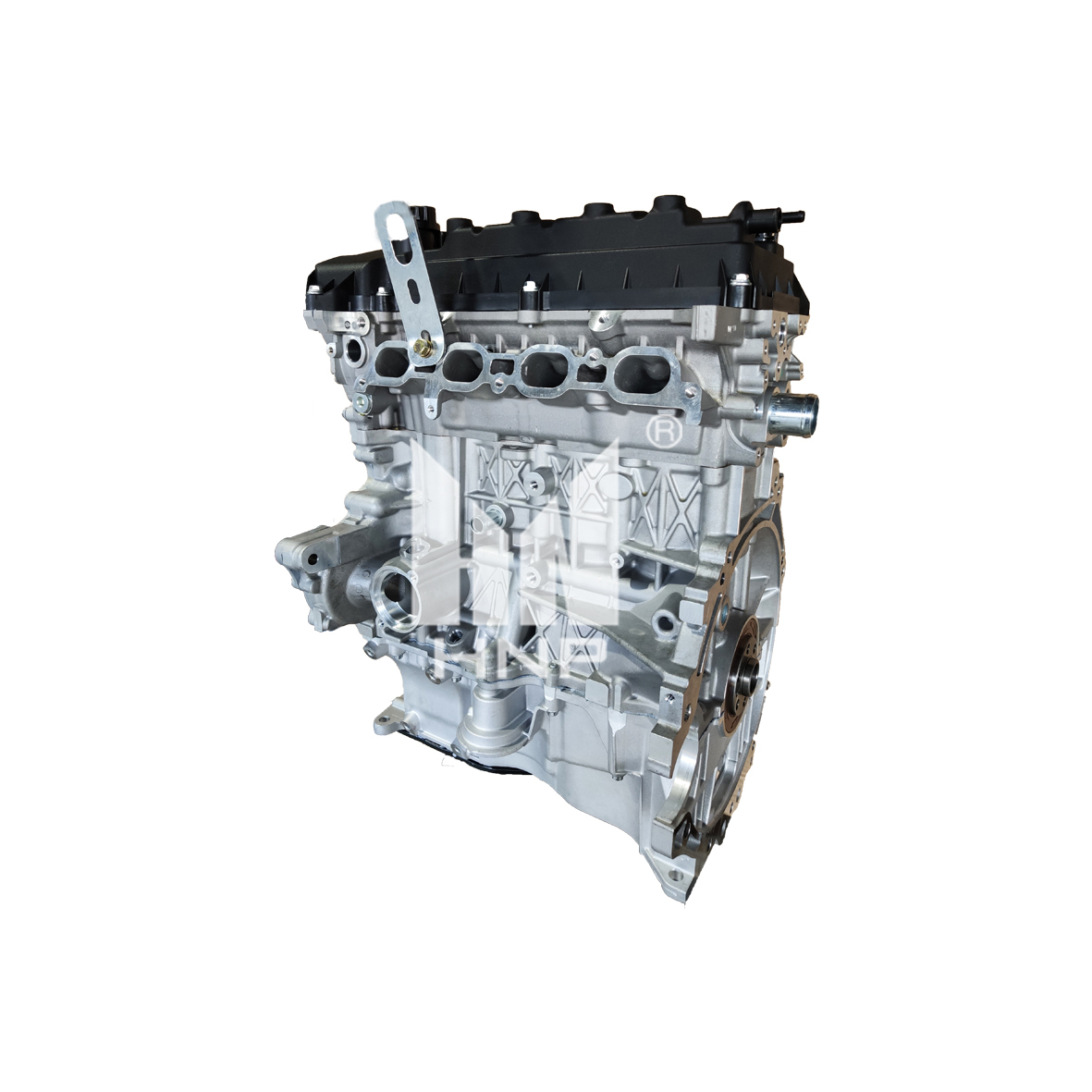

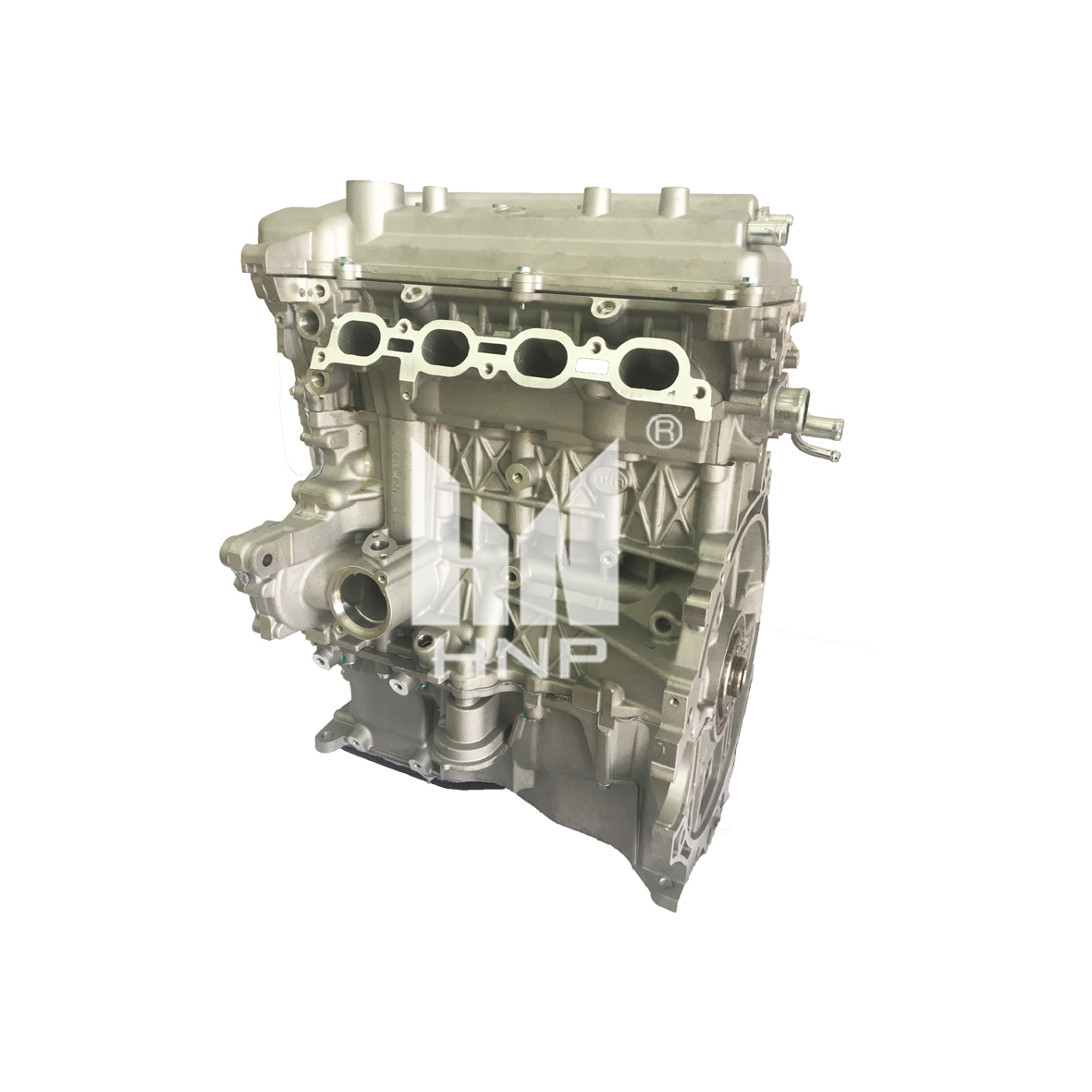

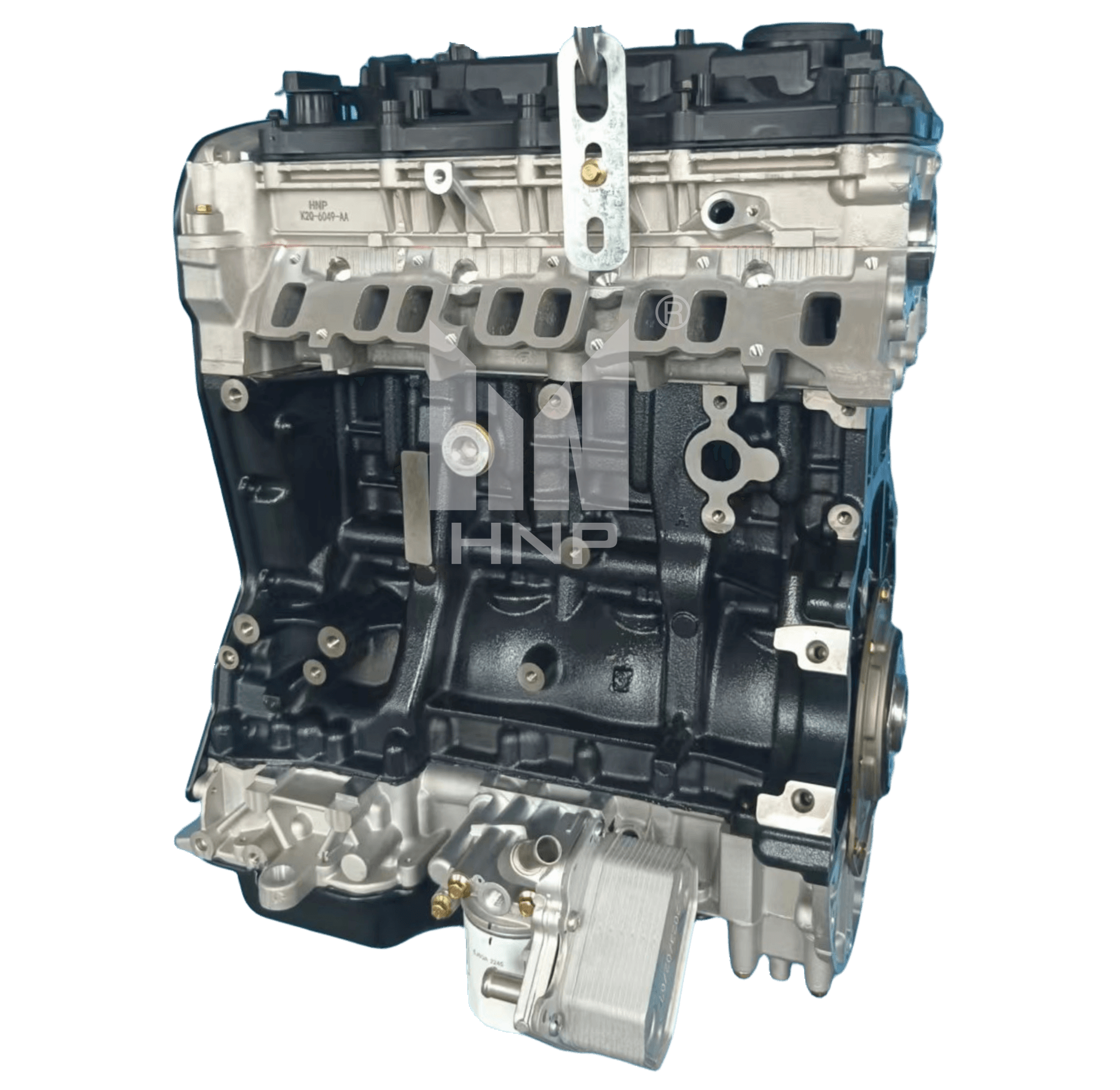

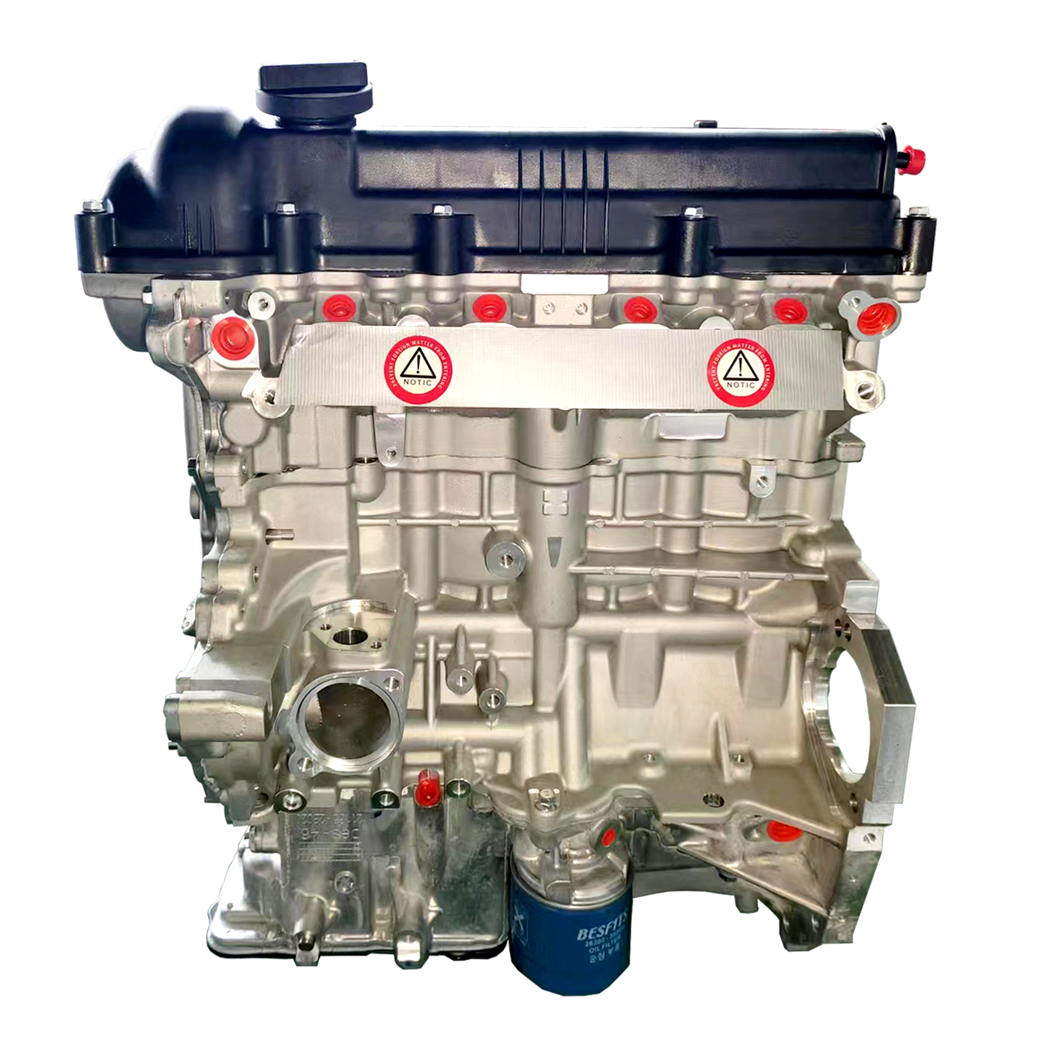

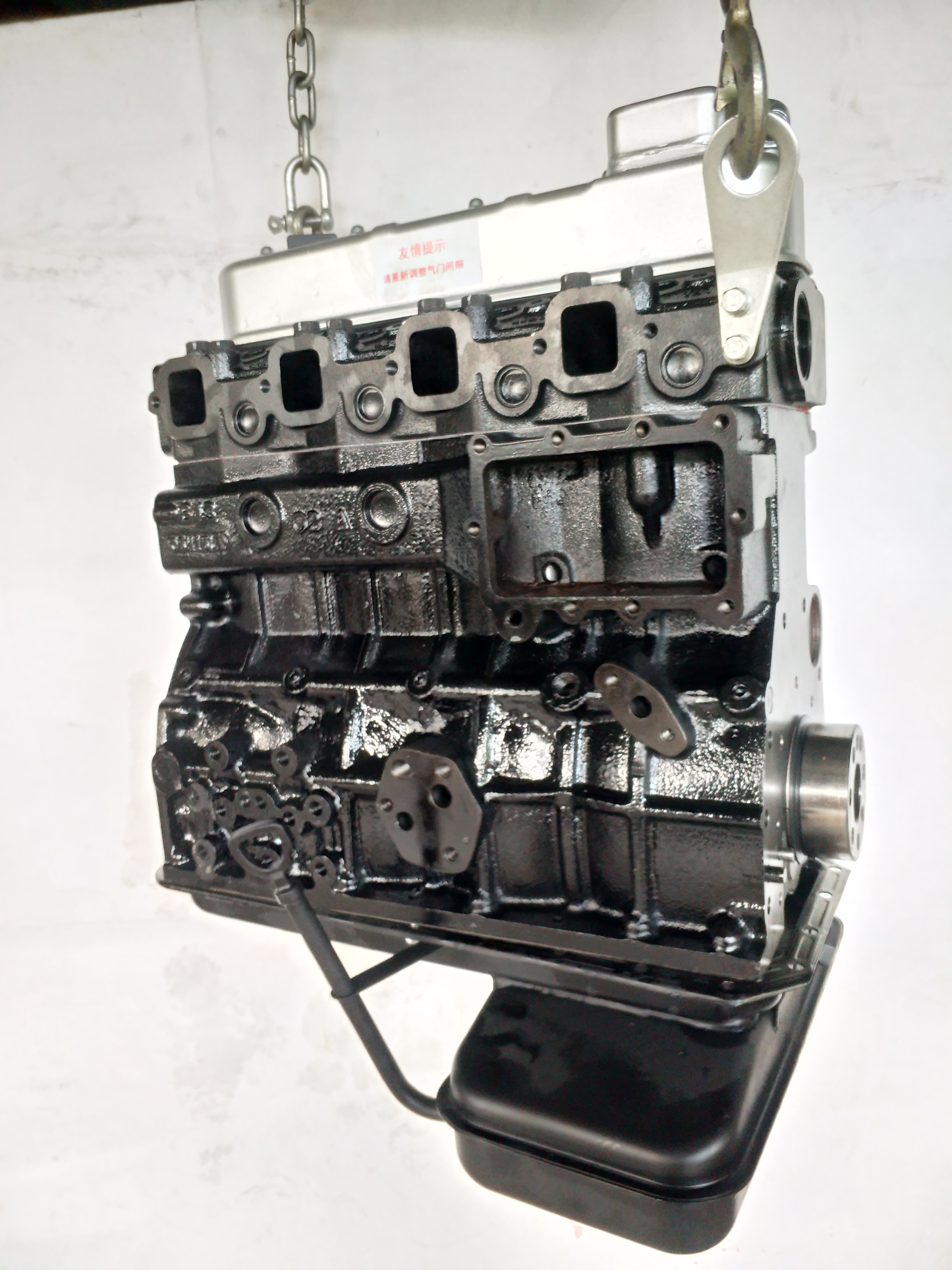

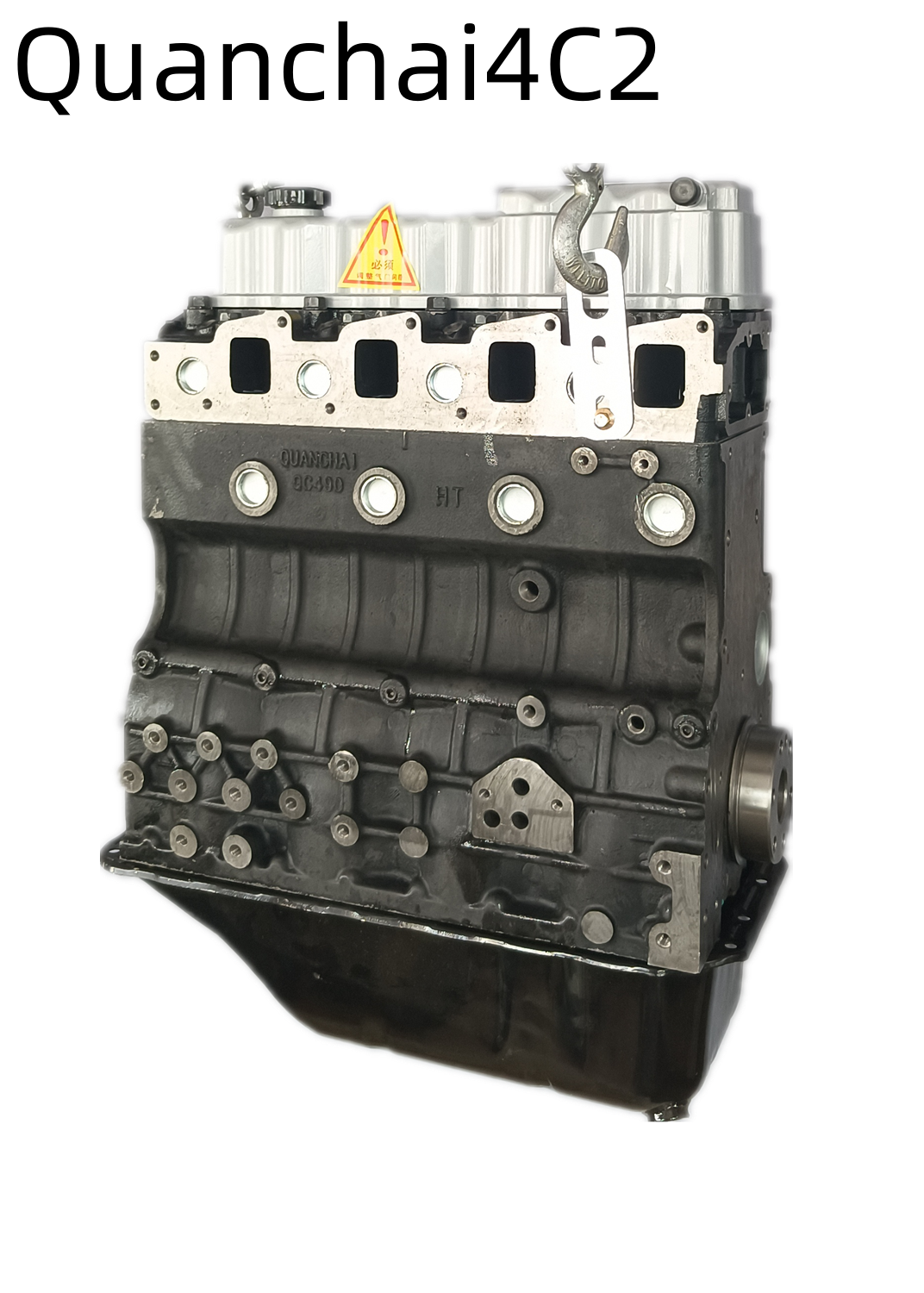

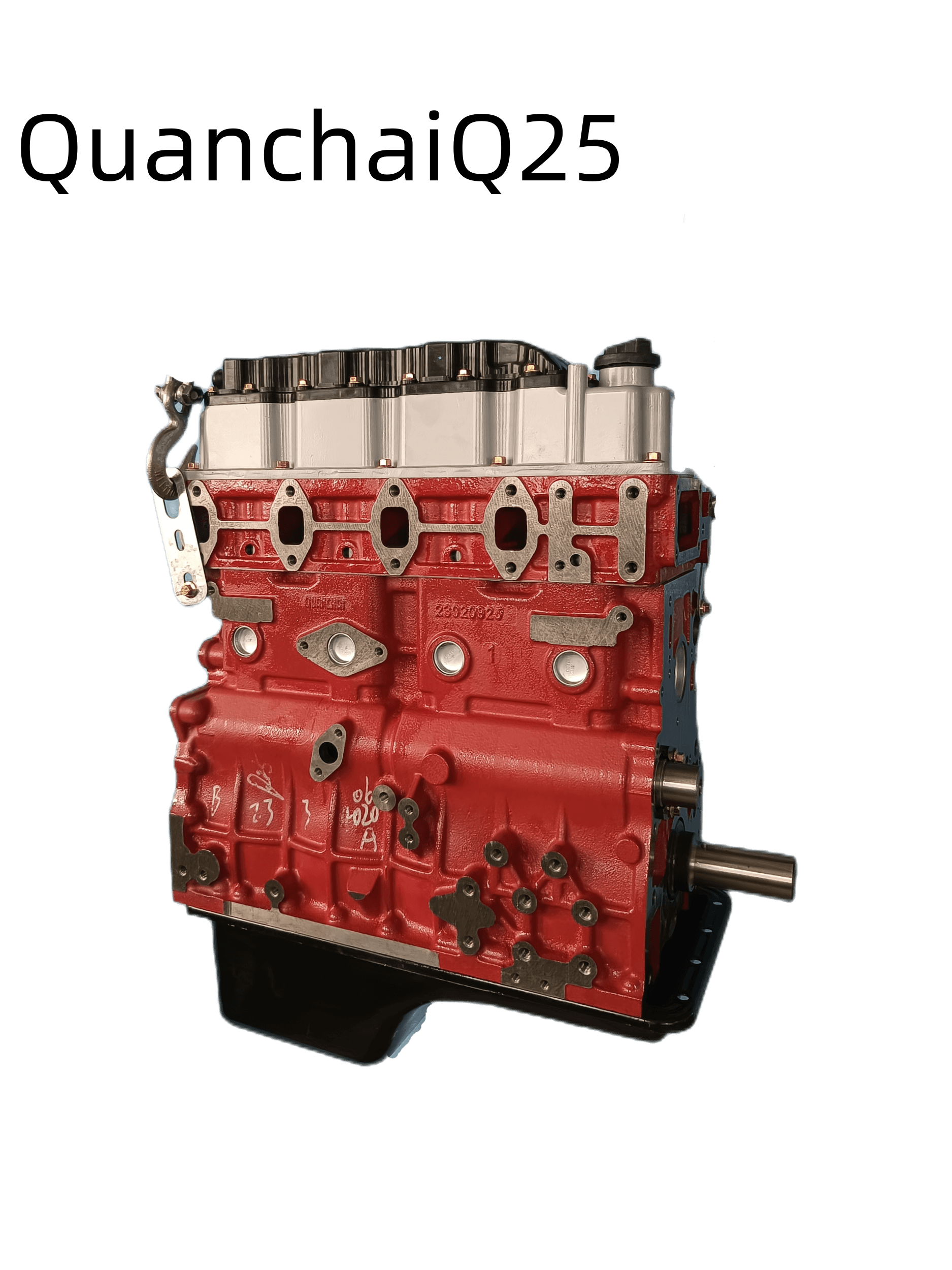

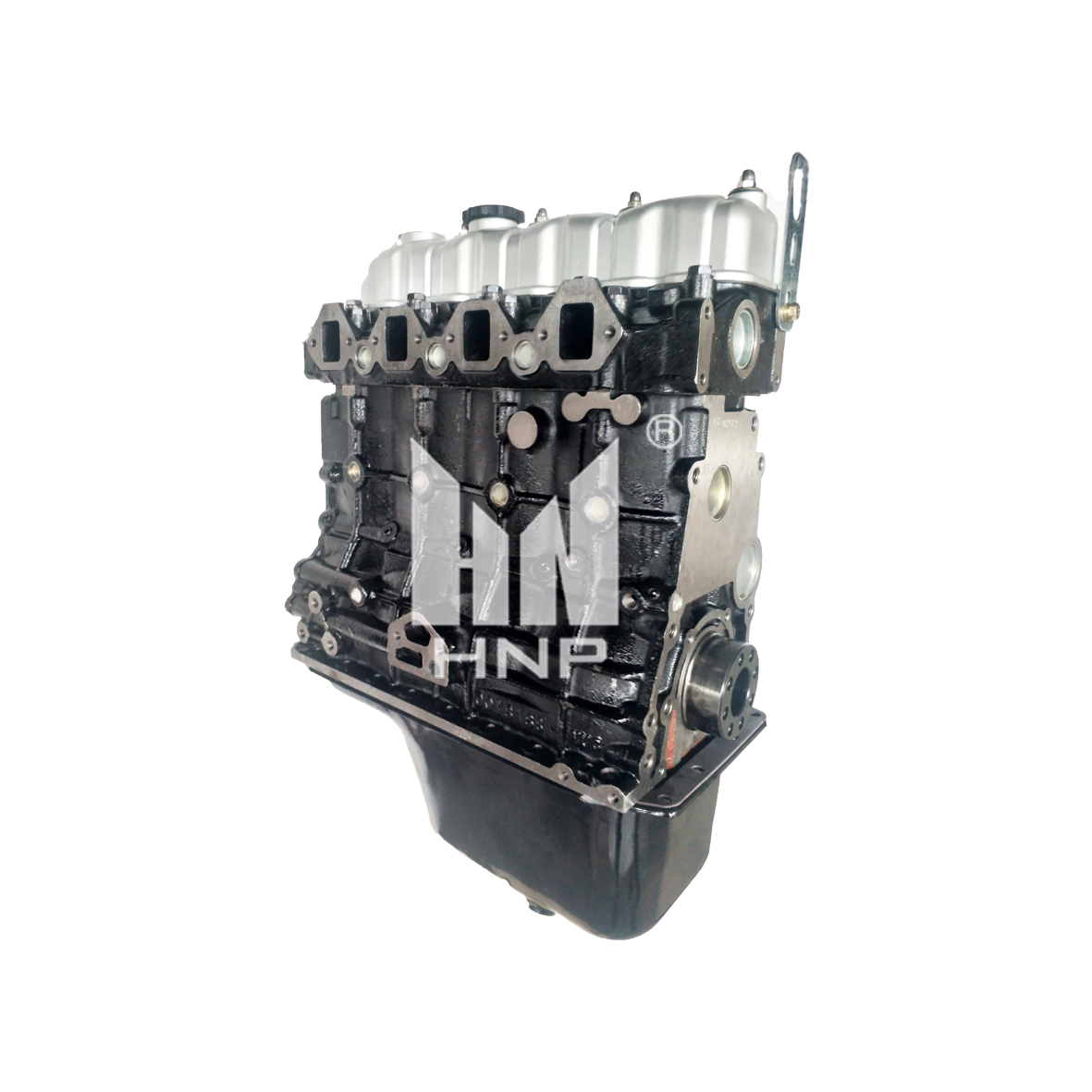

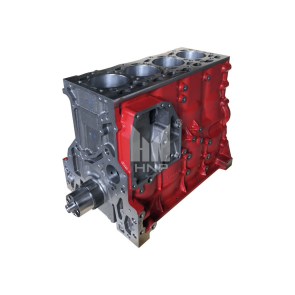

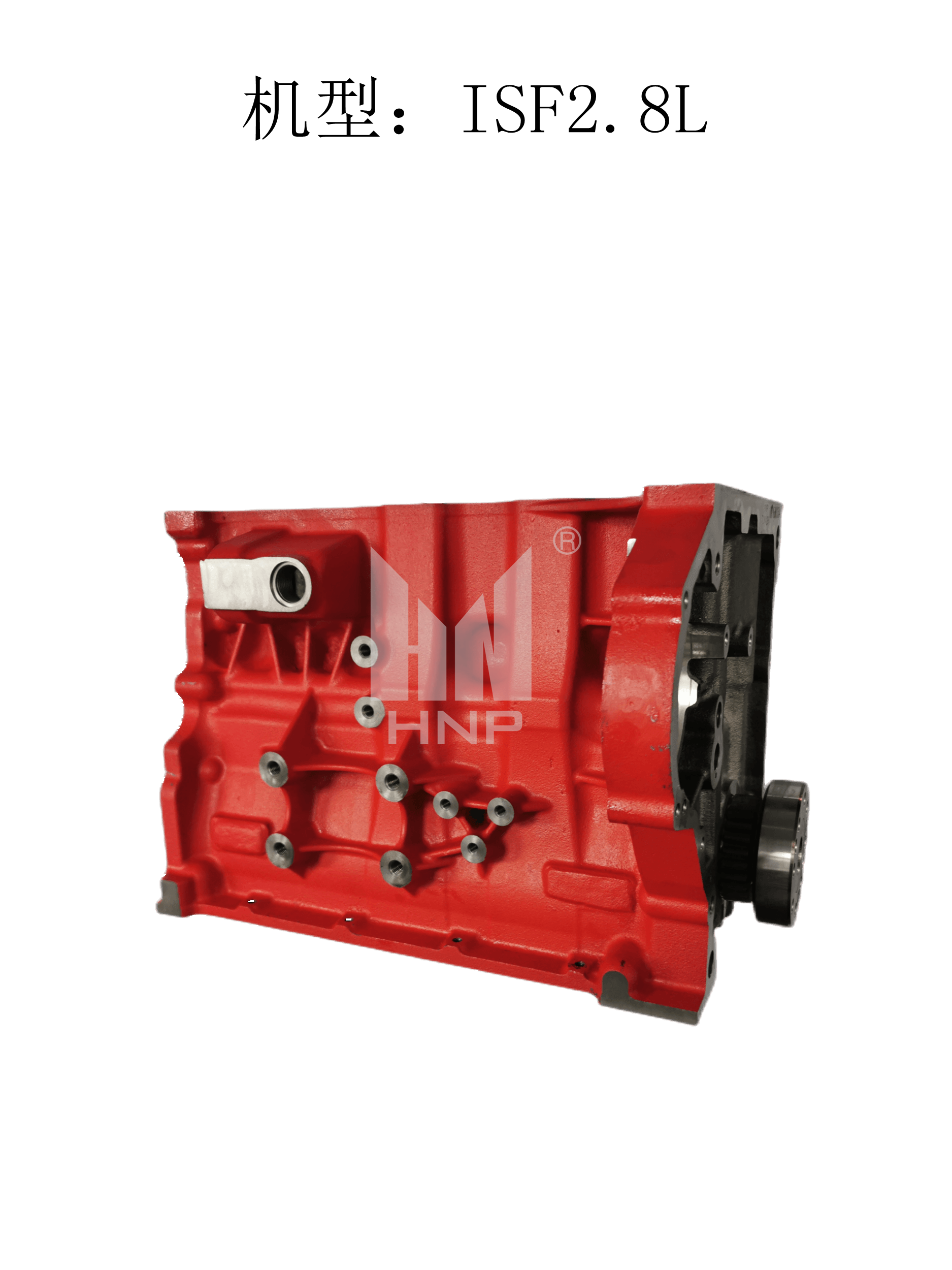

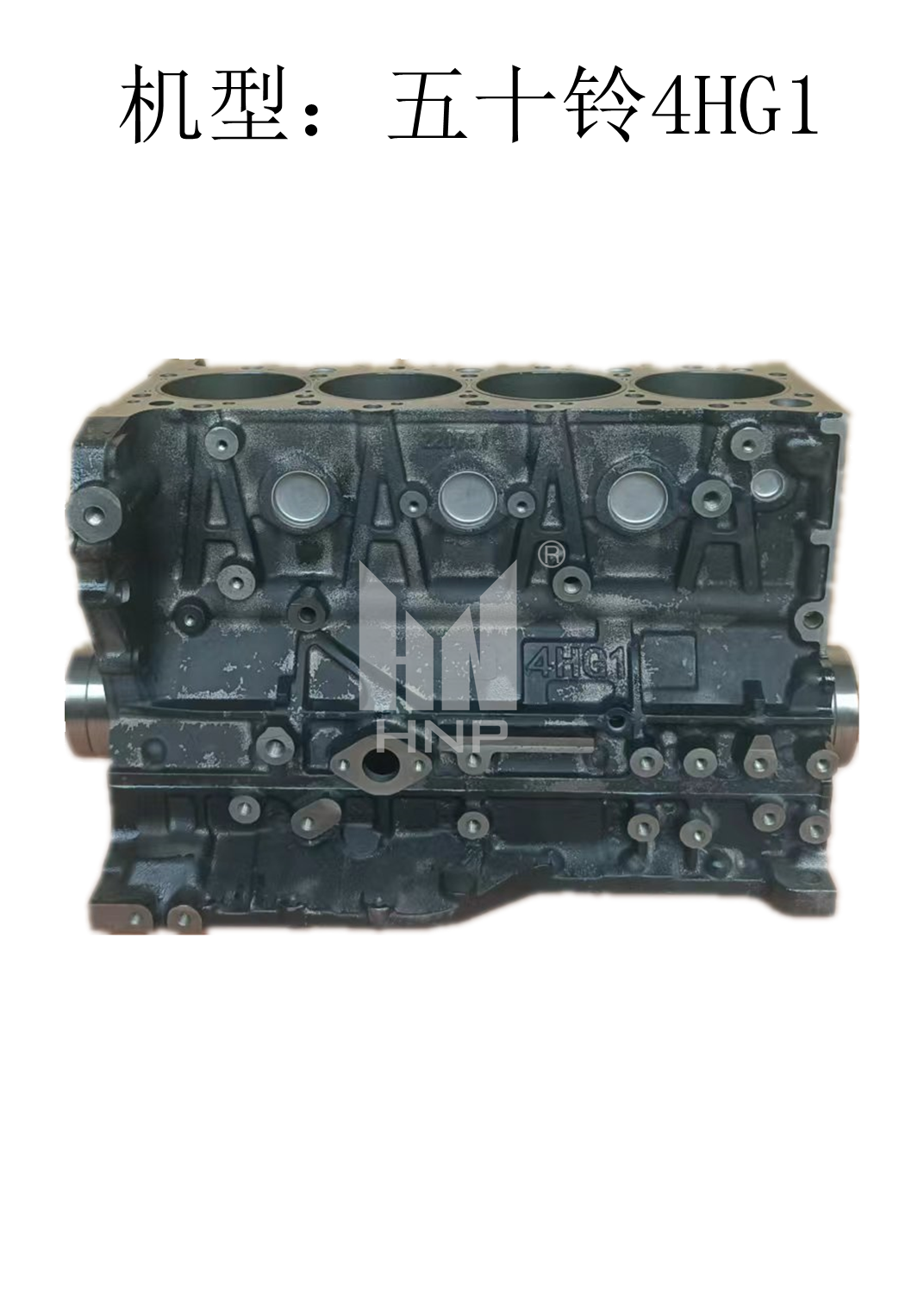

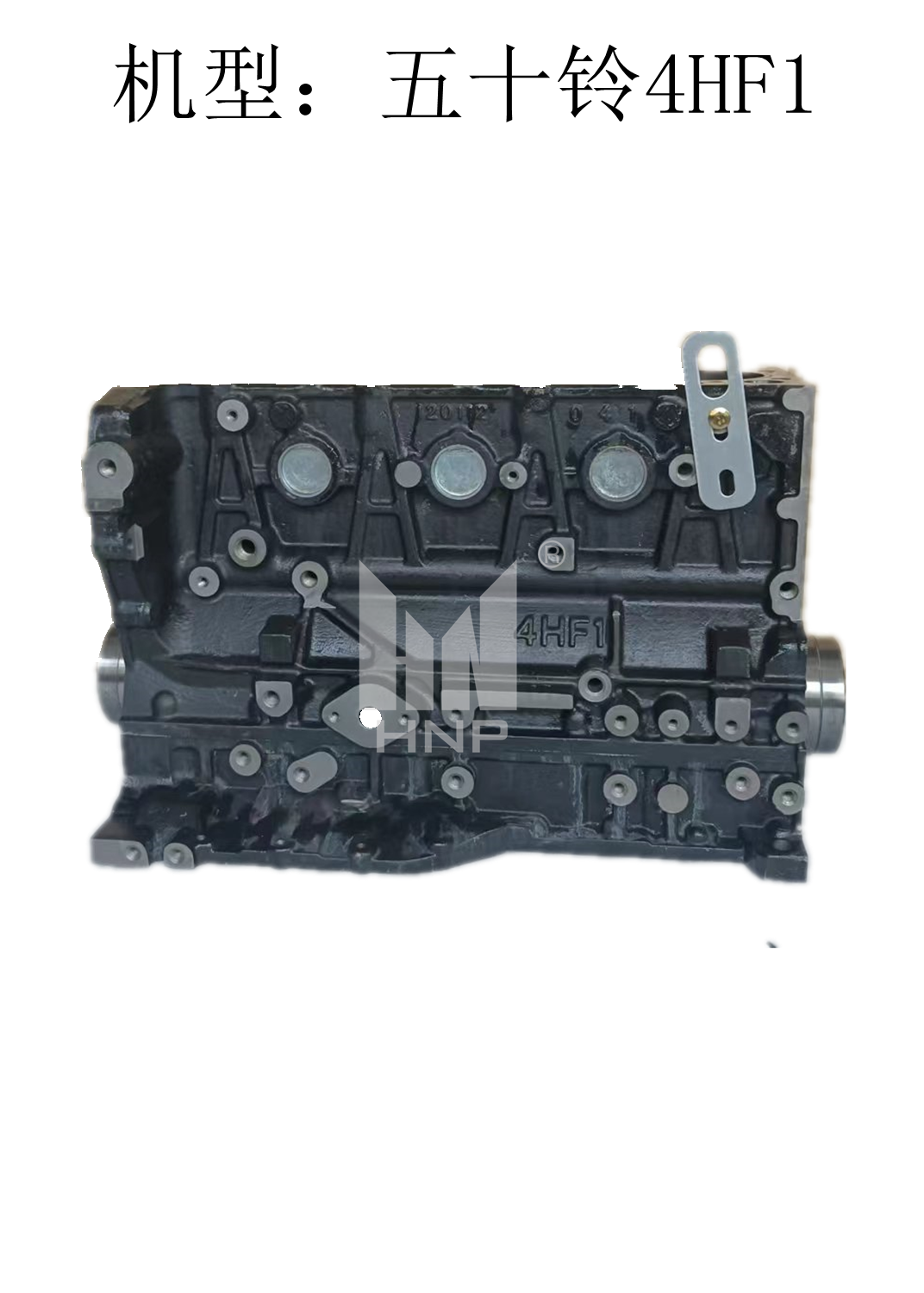

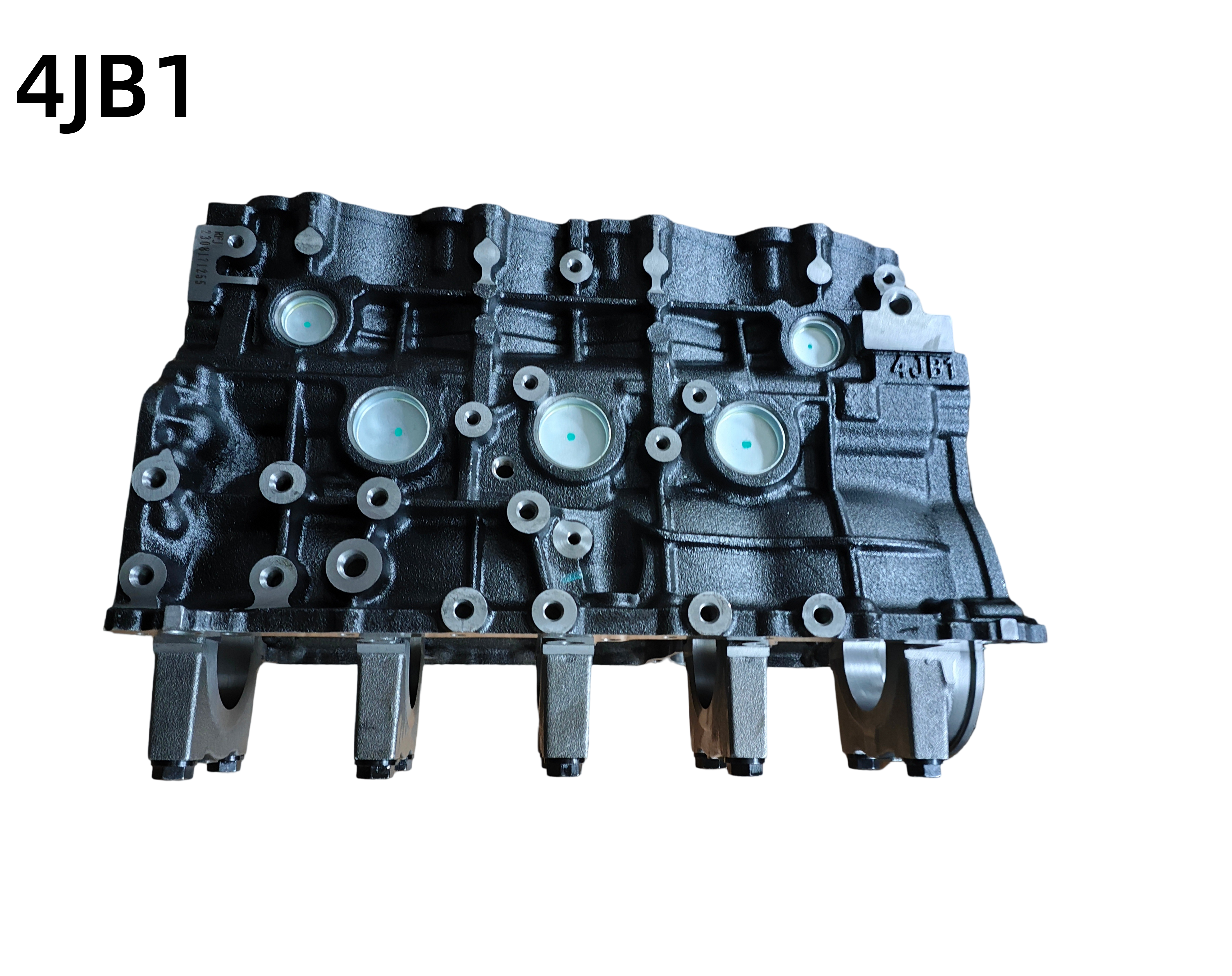

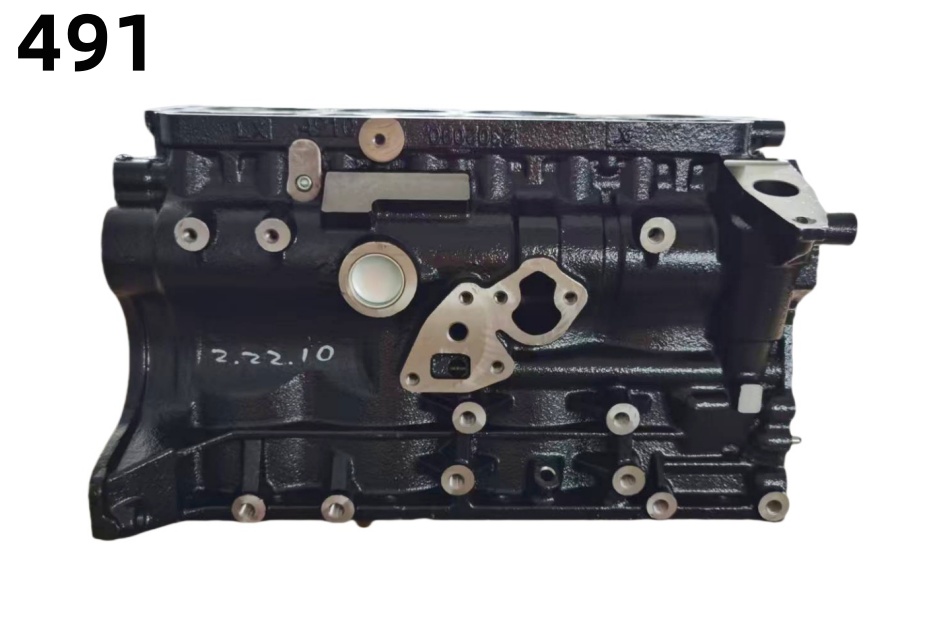

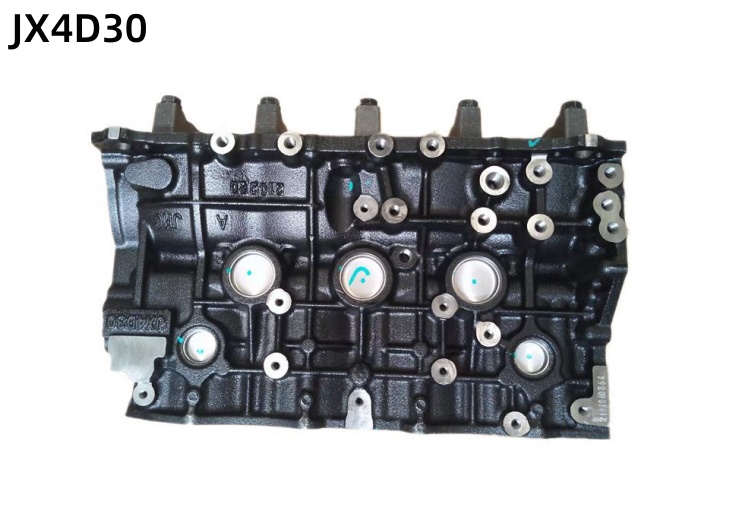

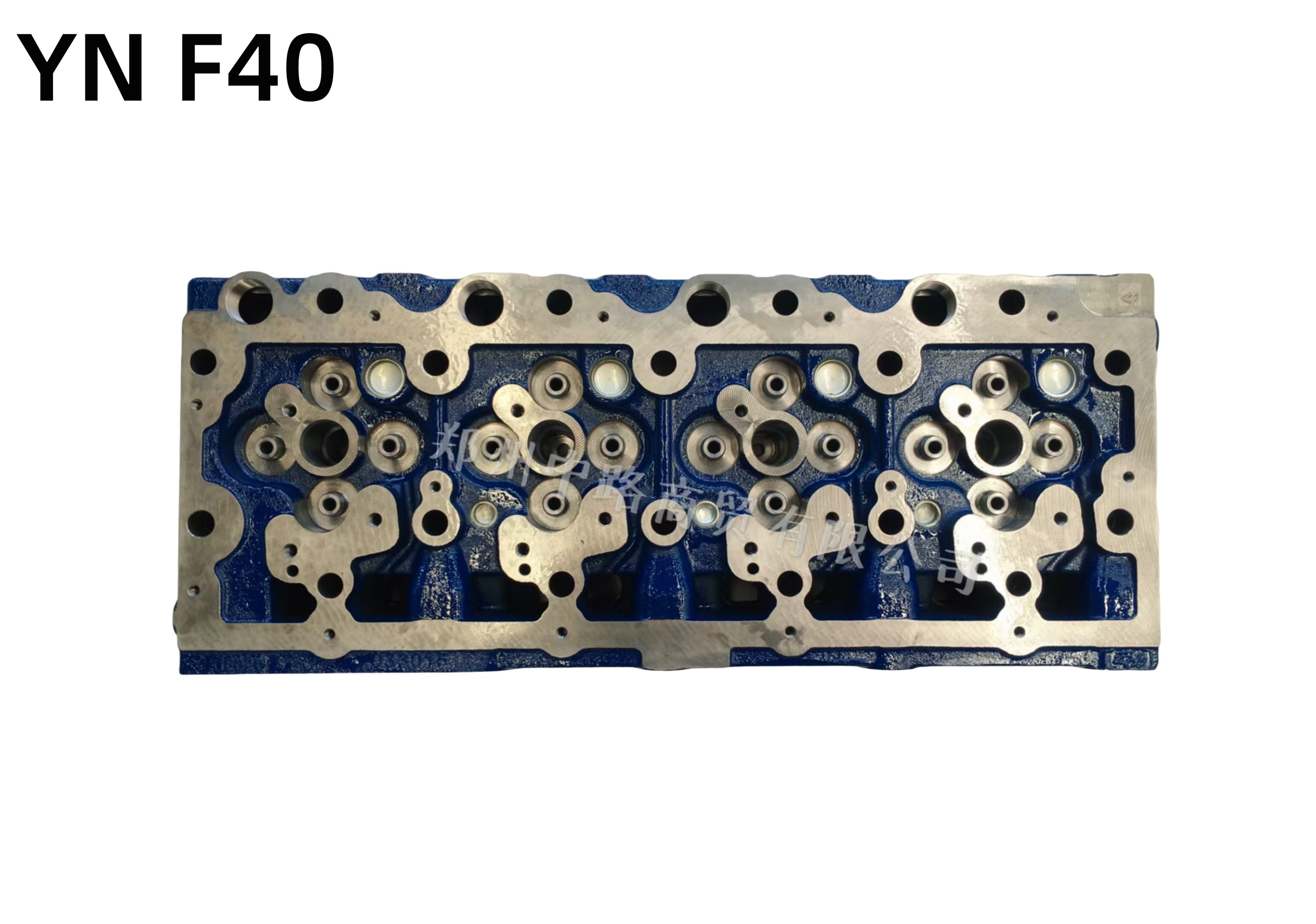

What Is a Short Block Engine?

A short block engine forms the foundation of any internal combustion engine. It's called a "short block" because it doesn't include everything you would find in a fully assembled engine.

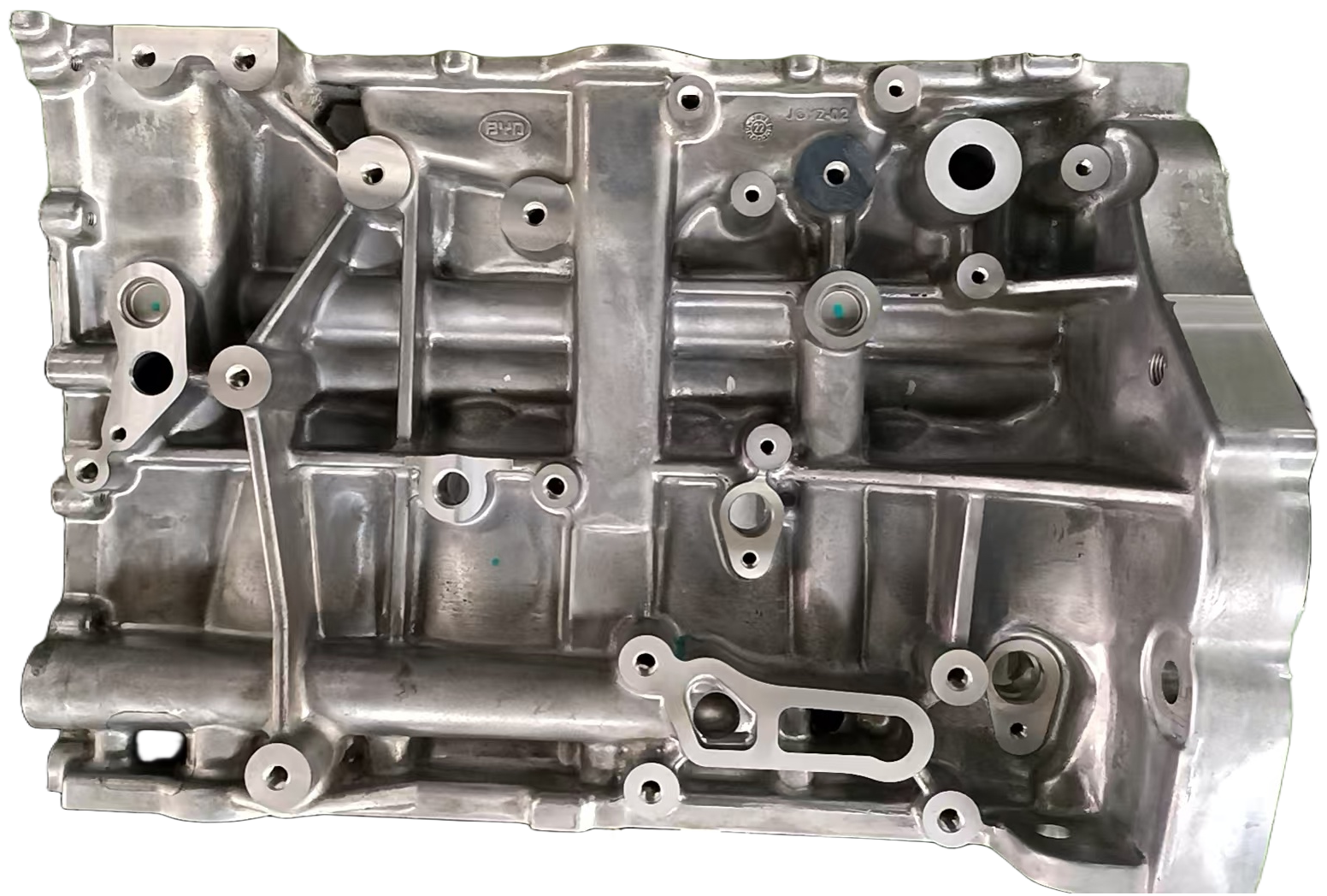

A standard short block typically consists of:

- Cylinder Block: The main body that houses the cylinders and supports other engine components.

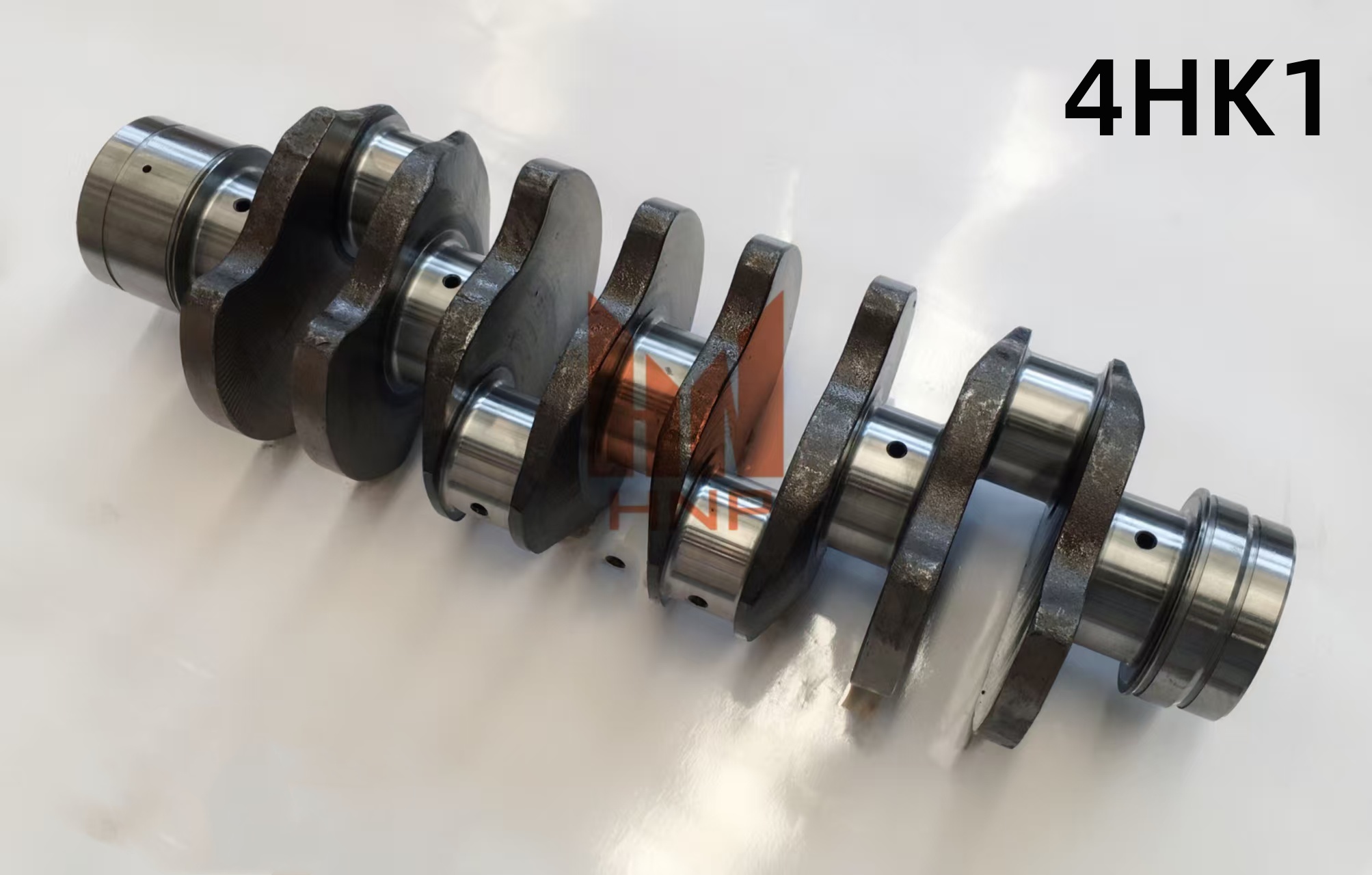

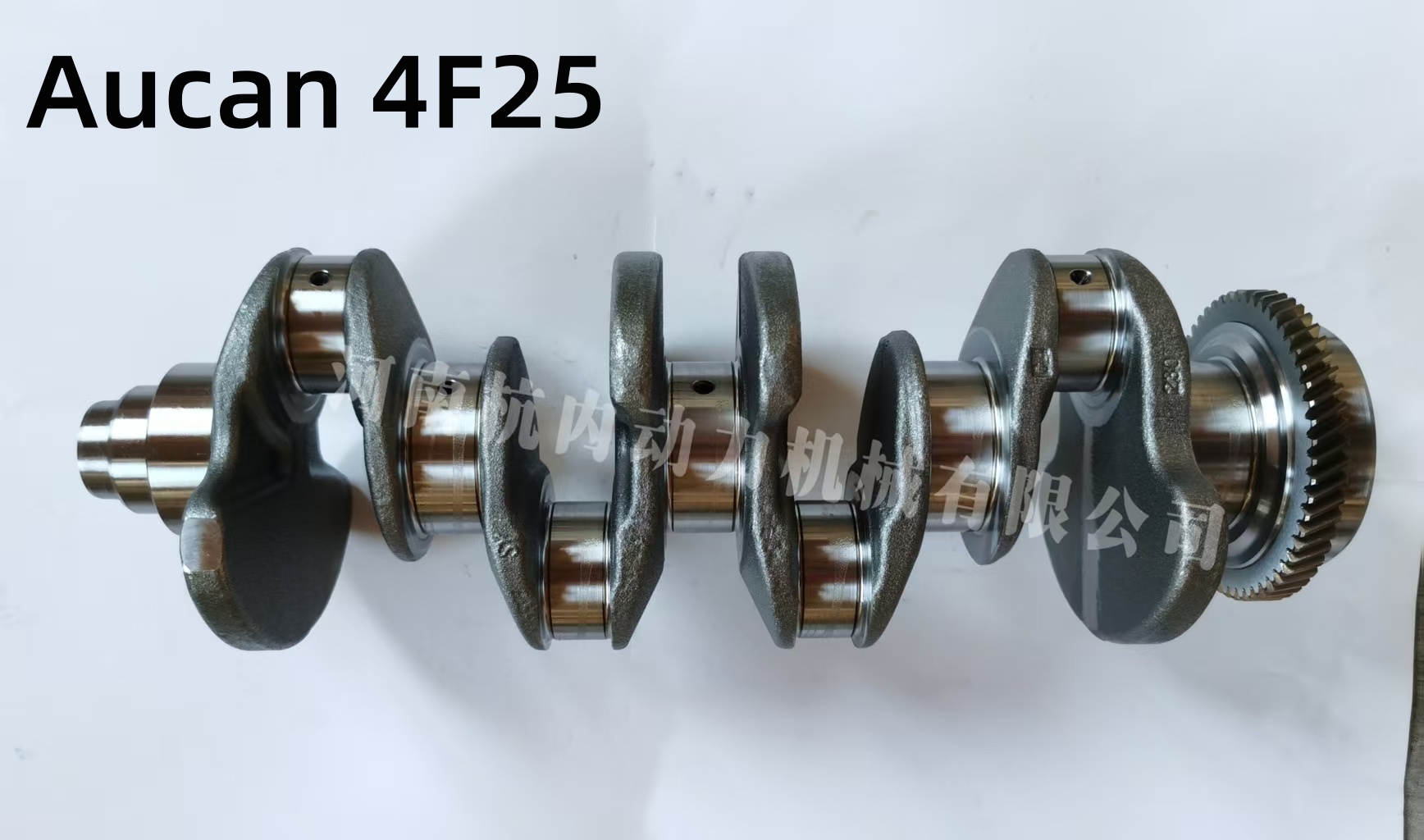

- Crankshaft: Converts the linear motion of the pistons into rotational motion.

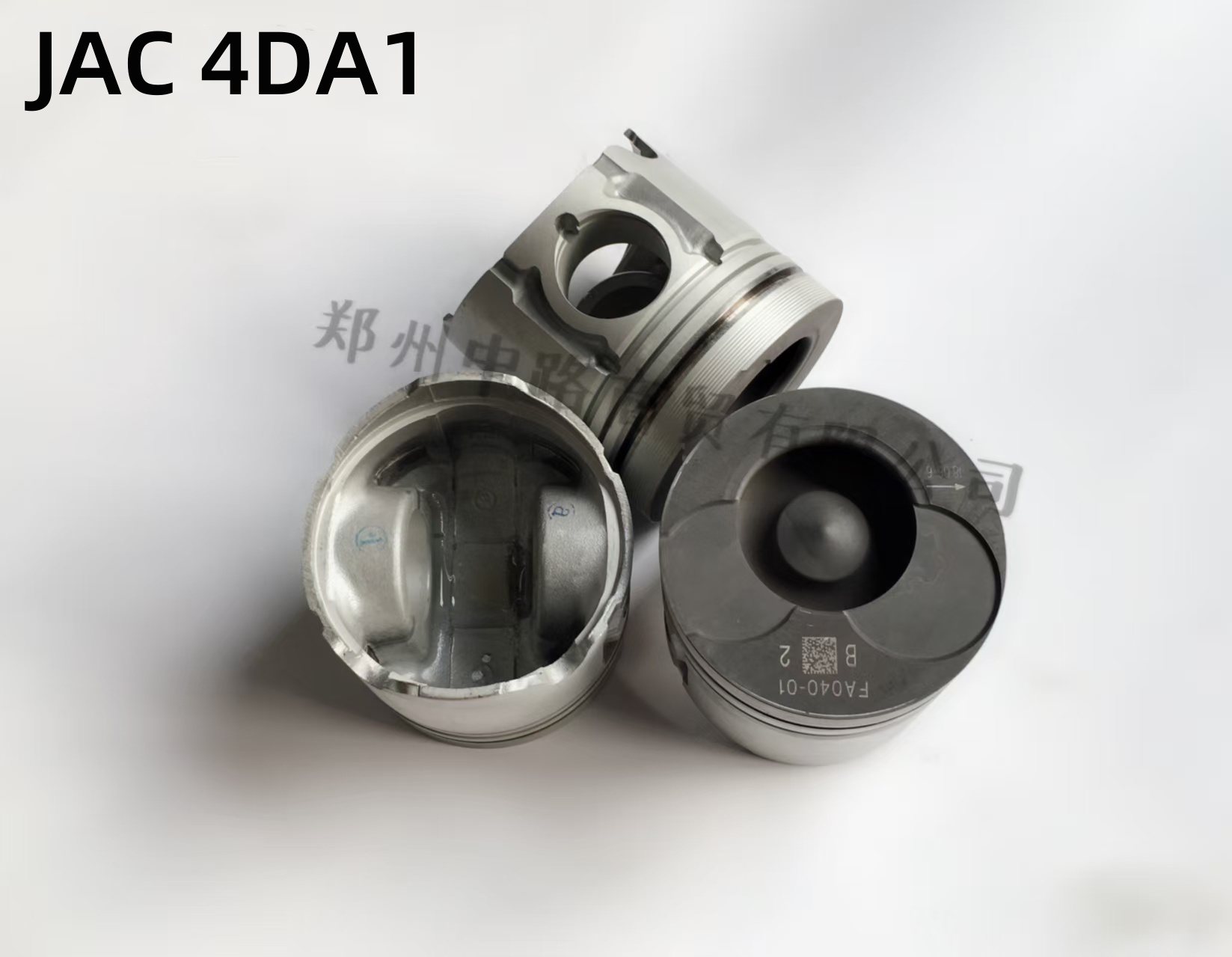

- Pistons: Move up and down within the cylinders to generate power.

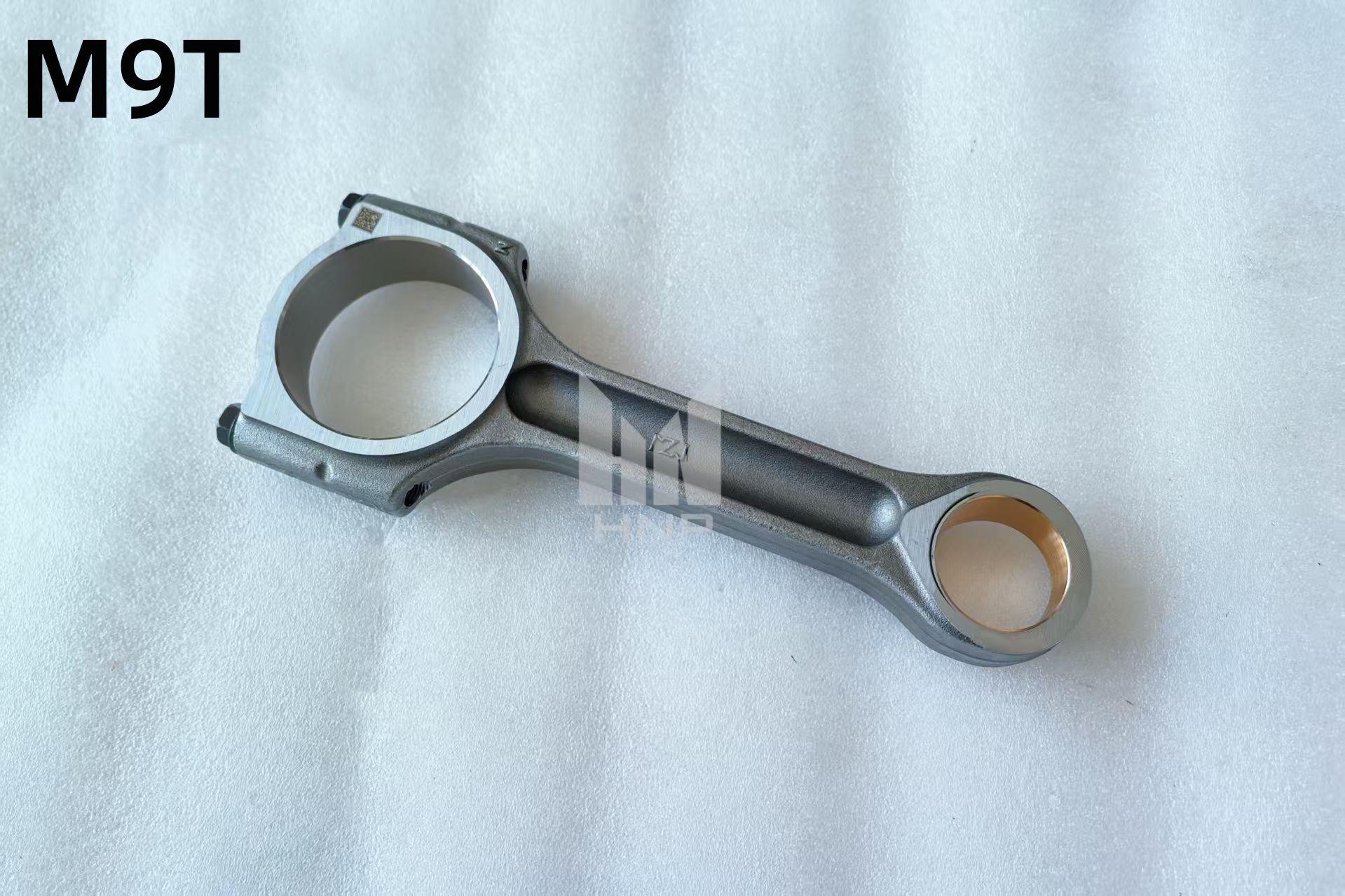

- Connecting Rods: Connect the pistons to the crankshaft.

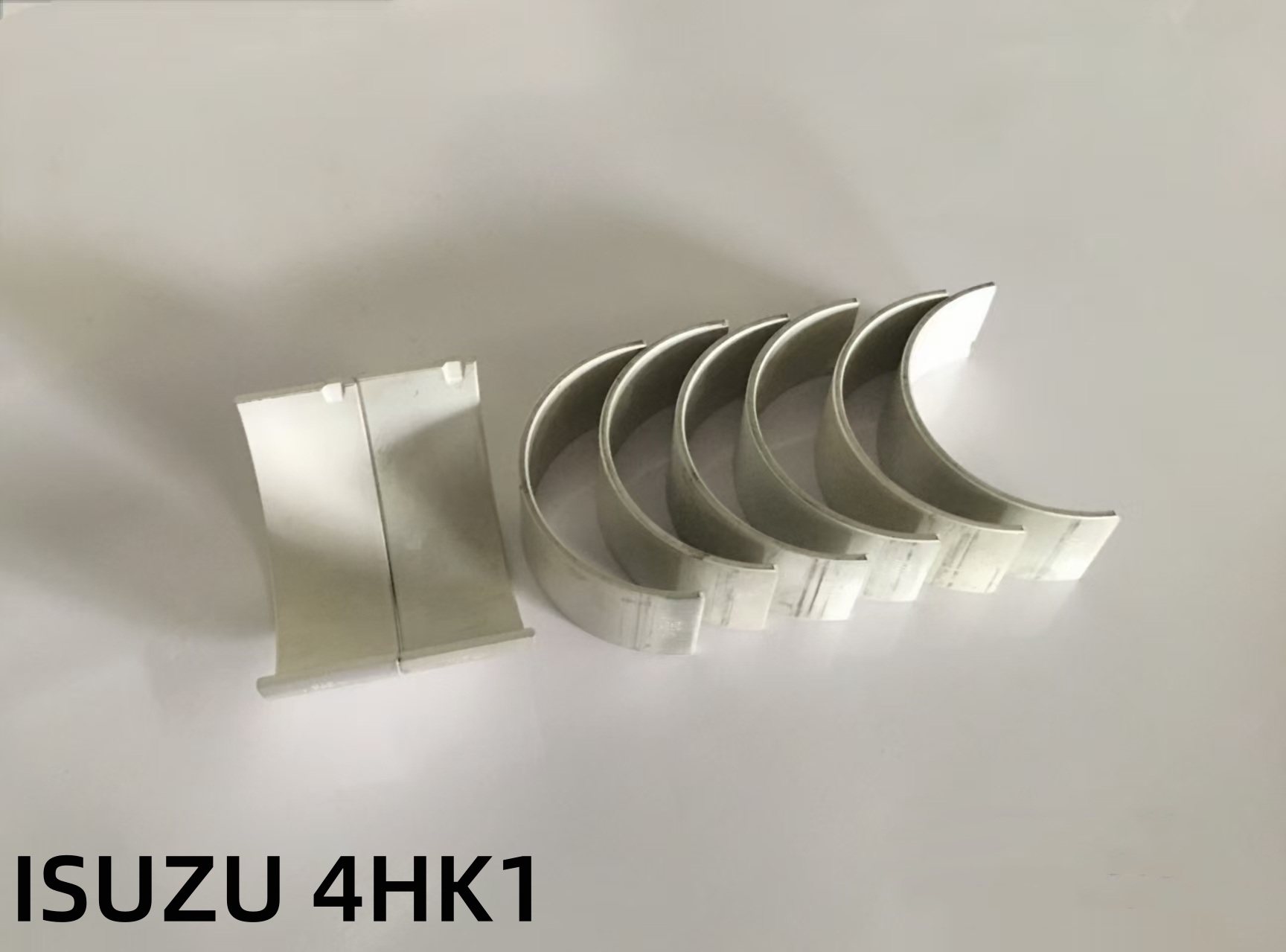

- Main Bearings and Rod Bearings: Support smooth rotation of the crankshaft and connecting rods.

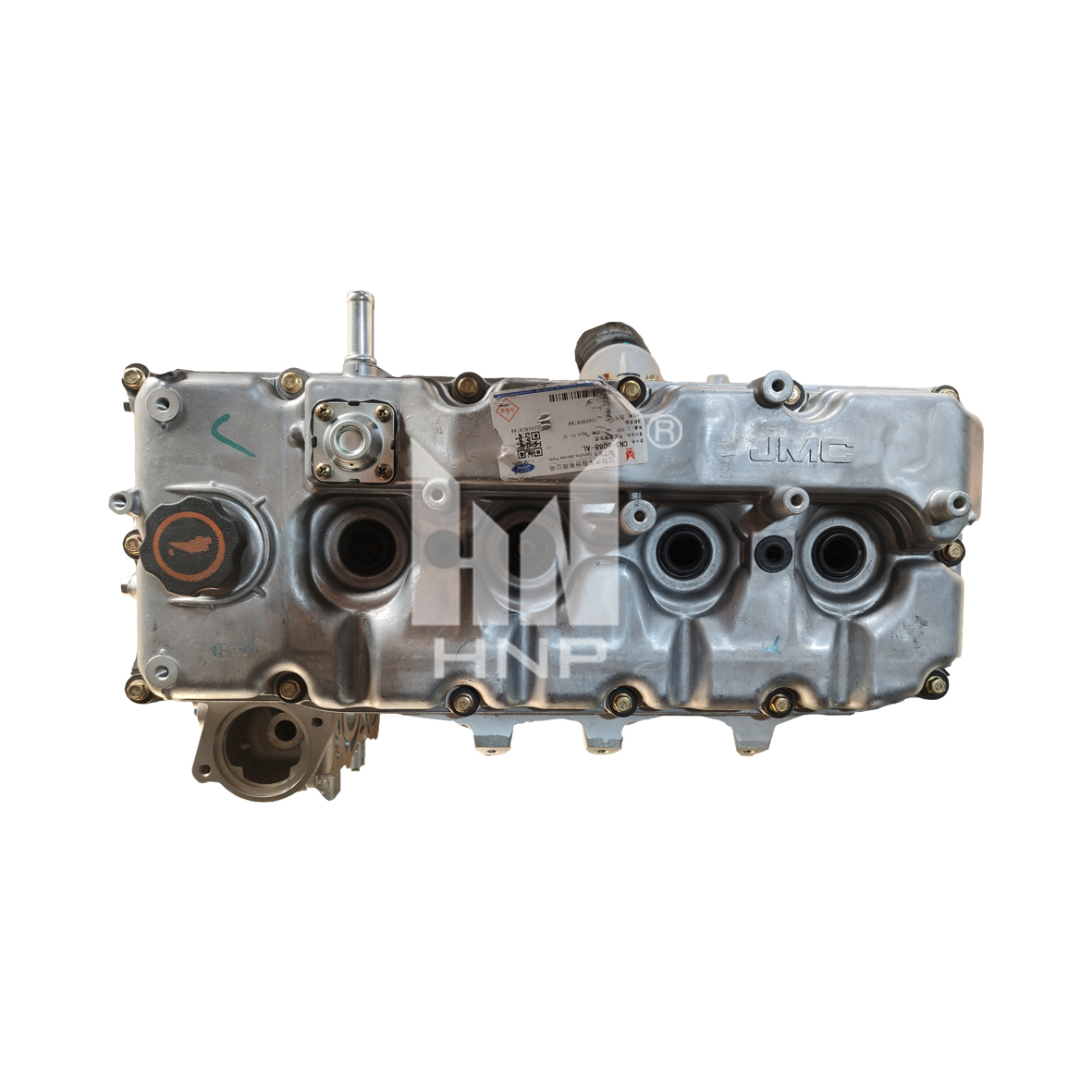

What Is Not Included?

Cylinder heads

Valve train (valves, springs, lifters, etc.)

Timing components (timing chain or belt)

Intake and exhaust manifolds

Oil pan (sometimes included depending on manufacturer)

In simple terms, a short block provides the "heart" of the engine without the "lungs" (cylinder heads) or "brain" (valve timing systems).

Short blocks are ideal when the lower end of an engine fails, but the upper components are still functional or easily repairable.

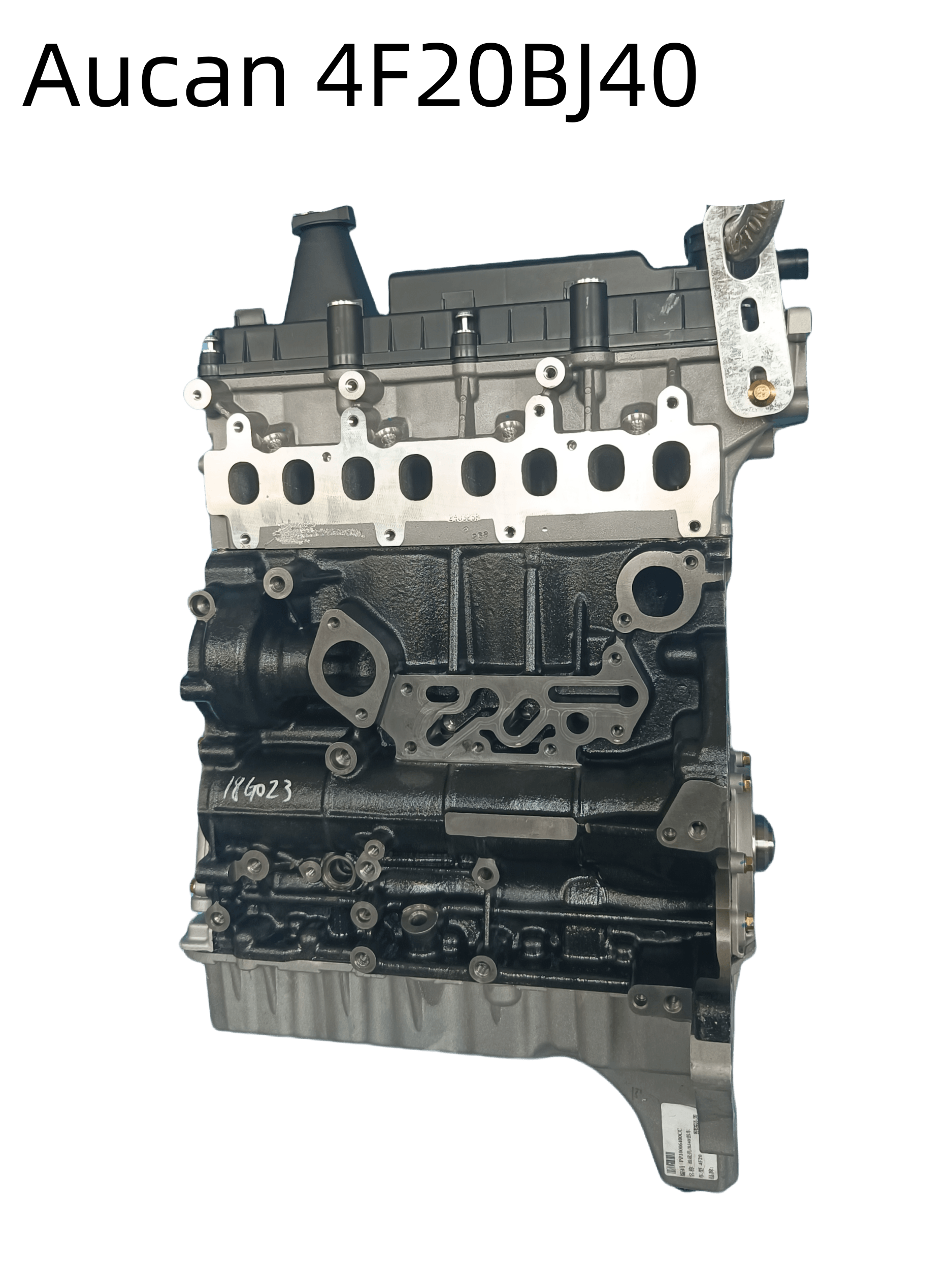

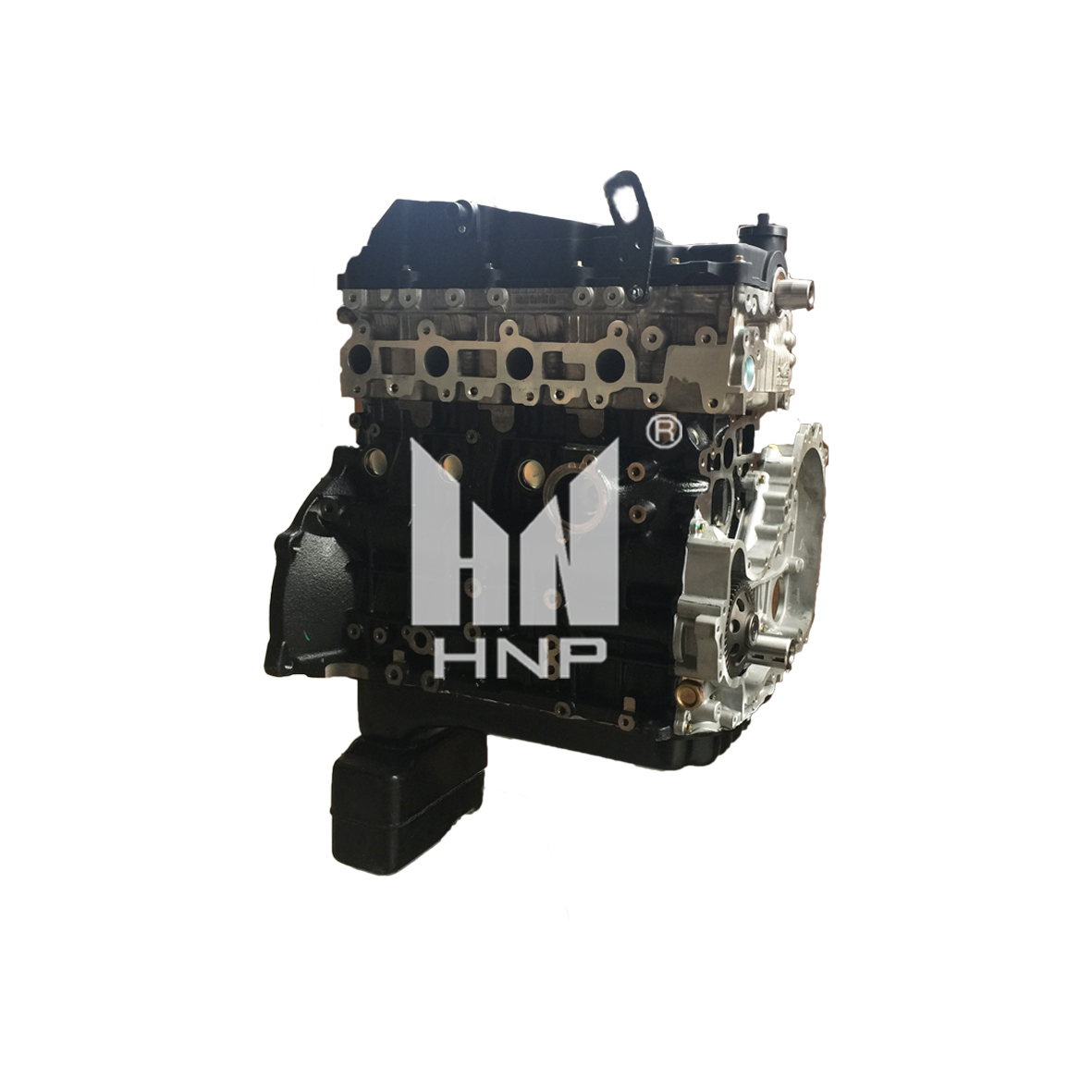

What Are Remanufactured Short Block Engines?

Remanufactured short block engines are previously used engines that have undergone a rigorous process to restore them to like-new — or even better than new — condition.

The remanufacturing process includes:

- Complete disassembly

- Detailed inspection

- Deep cleaning

- Precision machining

- Replacement of all critical wear components

- Professional reassembly

Unlike a simple "rebuilt" engine (which may only repair specific failures), remanufactured short block engines address the entire engine systematically, ensuring that it meets or exceeds OEM specifications.

Many remanufacturers also incorporate upgrades to known weak points, making remanufactured short blocks even more reliable than some factory versions.

Why Choose a Remanufactured Short Block Engine?

There are many compelling reasons to opt for remanufactured short block engines when faced with major engine issues. Let's break them down:

1. Significant Cost Savings

Purchasing a brand-new engine can cost tens of thousands of dollars, especially for high-end or diesel models. A remanufactured short block engine provides a budget-friendly alternative without compromising on reliability.

For instance, replacing only the damaged lower end — rather than the entire engine assembly — means you save on parts, labor, and ancillary components.

2. Trusted Reliability

Today's remanufactured short block engines undergo strict quality control. Reputable remanufacturers use advanced inspection tools like:

Ultrasonic crack detection

Laser measurement systems

Computer-guided machining equipment

These processes ensure that remanufactured engines meet modern standards for durability and precision.

3. Environmentally Responsible

Choosing a remanufactured short block engine helps reduce waste:

- 85% less raw material is used compared to building a new engine.

- Energy consumption is reduced by up to 50%.

- Landfill waste is significantly minimized.

By investing in remanufacturing, you actively contribute to more sustainable vehicle ownership.

4. Availability and Quick Turnaround

When you opt for a short block engine replacement, you often face much shorter lead times than ordering a new engine. Many remanufactured engines are readily available, meaning your car can get back on the road faster.

5. Opportunity for Performance Upgrades

In performance or custom builds, remanufactured short block engines can be tailored with stronger internals, better pistons, and upgraded bearings — offering an improvement over stock performance.

When Should You Consider a Short Block Engine Replacement?

Knowing when it's time for a short block engine replacement can save you from a complete vehicle replacement. Here are situations when replacing the short block makes sense:

1. Bottom-End Engine Failure

Failures limited to the crankshaft, pistons, rods, or block are perfect candidates. Examples include:

- Spun rod bearings

- Cracked blocks

- Broken piston skirts

2. High Mileage Engines

Over time, wear and tear on pistons, cylinders, and crankshafts lead to performance loss. If your vehicle is burning oil, losing compression, or experiencing frequent bottom-end noise, a short block engine replacement might be smarter than patching up individual parts.

3. Catastrophic Engine Overheating

If overheating has caused block warping or cracks but left the heads salvageable, replacing just the short block is cost-effective.

4. Restoration Projects

Classic car enthusiasts often turn to remanufactured short block engines when restoring older vehicles where the heads are still usable but the bottom end is worn or seized.

The Remanufacturing Process: A Deep Dive

Understanding how remanufactured short block engines are made can give you confidence in your investment. Here's a detailed look at each step:

Step 1: Core Acceptance and Inspection

The used engine, called the "core," is thoroughly inspected. Remanufacturers check for:

- Cracks in the block using magnetic particle inspection or dye penetrant

- Excessive wear on bearing surfaces

- Warped crankshafts or twisted connecting rods

- Only acceptable cores are moved forward in the process.

Step 2: Disassembly

The engine is completely disassembled into individual components. Fasteners, bearings, and soft components (like seals and gaskets) are discarded.

Step 3: Cleaning

Cleaning is critical:

- Chemical baths dissolve oil sludge and carbon buildup.

- Shot blasting removes stubborn rust or deposits.

- Ultrasonic cleaning removes contaminants from oil galleries and coolant passages.

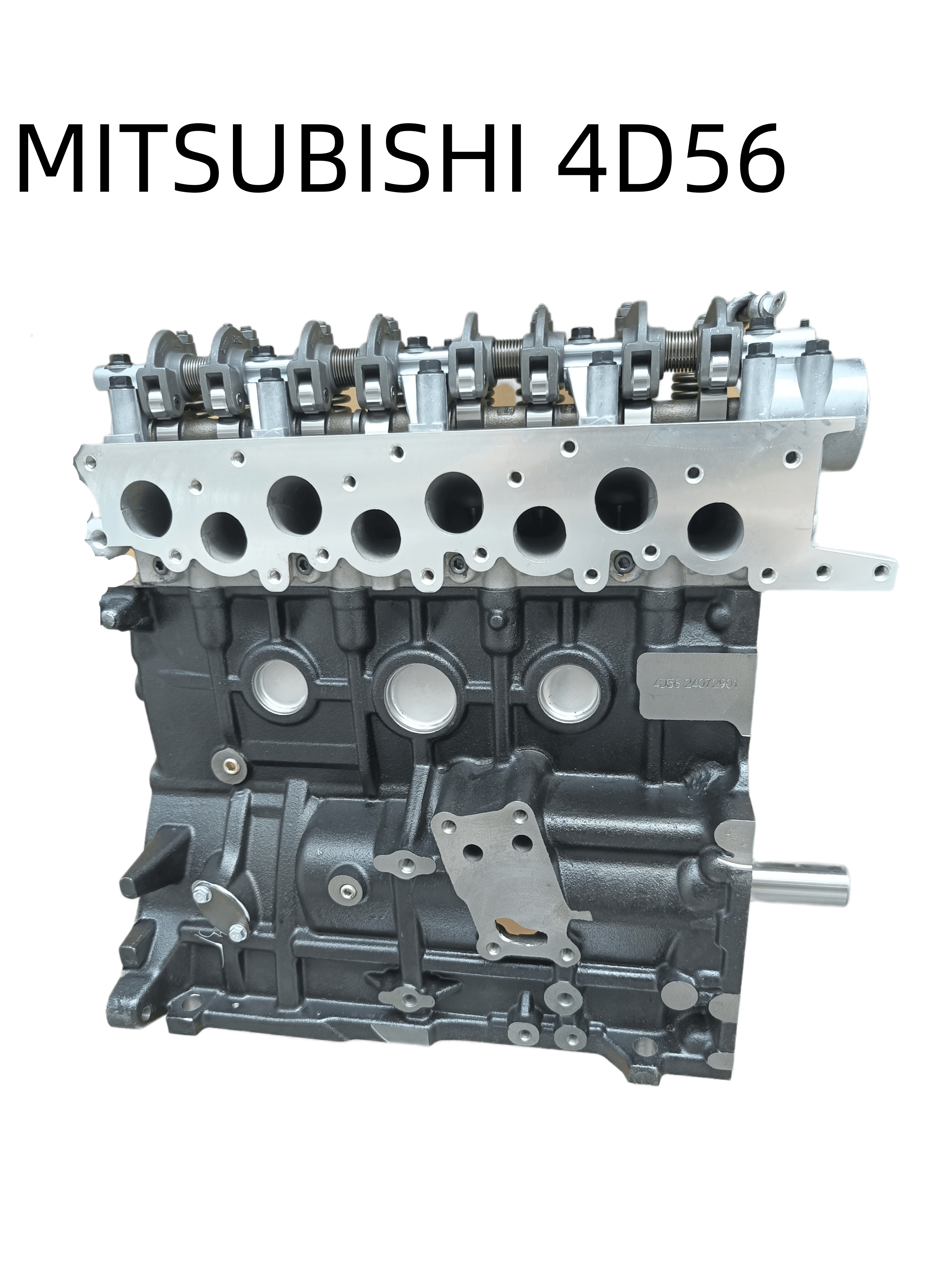

Step 4: Precision Machining

Machining restores critical surfaces:

- Cylinders are bored and honed to exact tolerances.

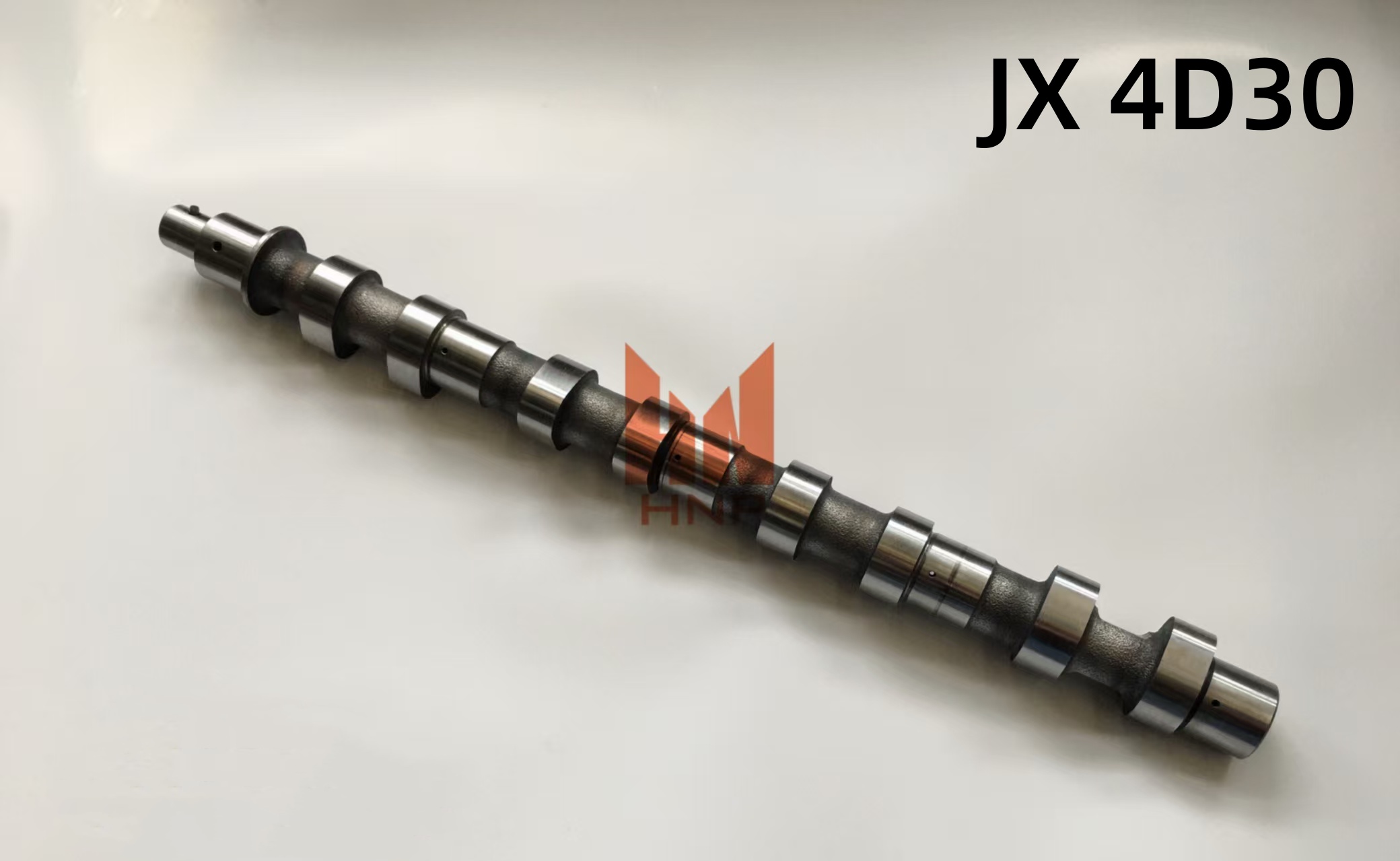

- Crankshafts are ground and polished.

- Deck surfaces are resurfaced for flatness.

- Machining ensures that all clearances meet strict OEM or better-than-OEM standards.

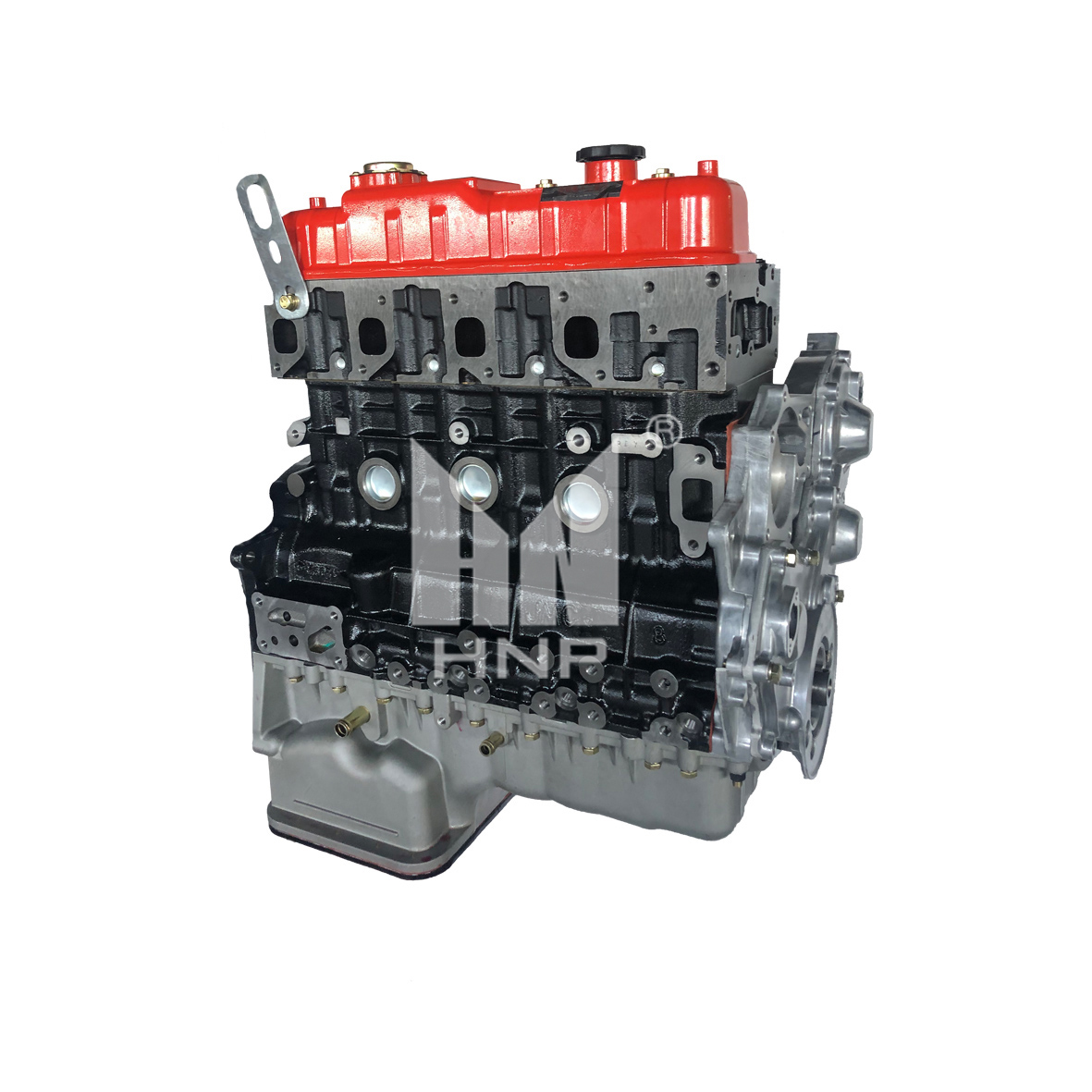

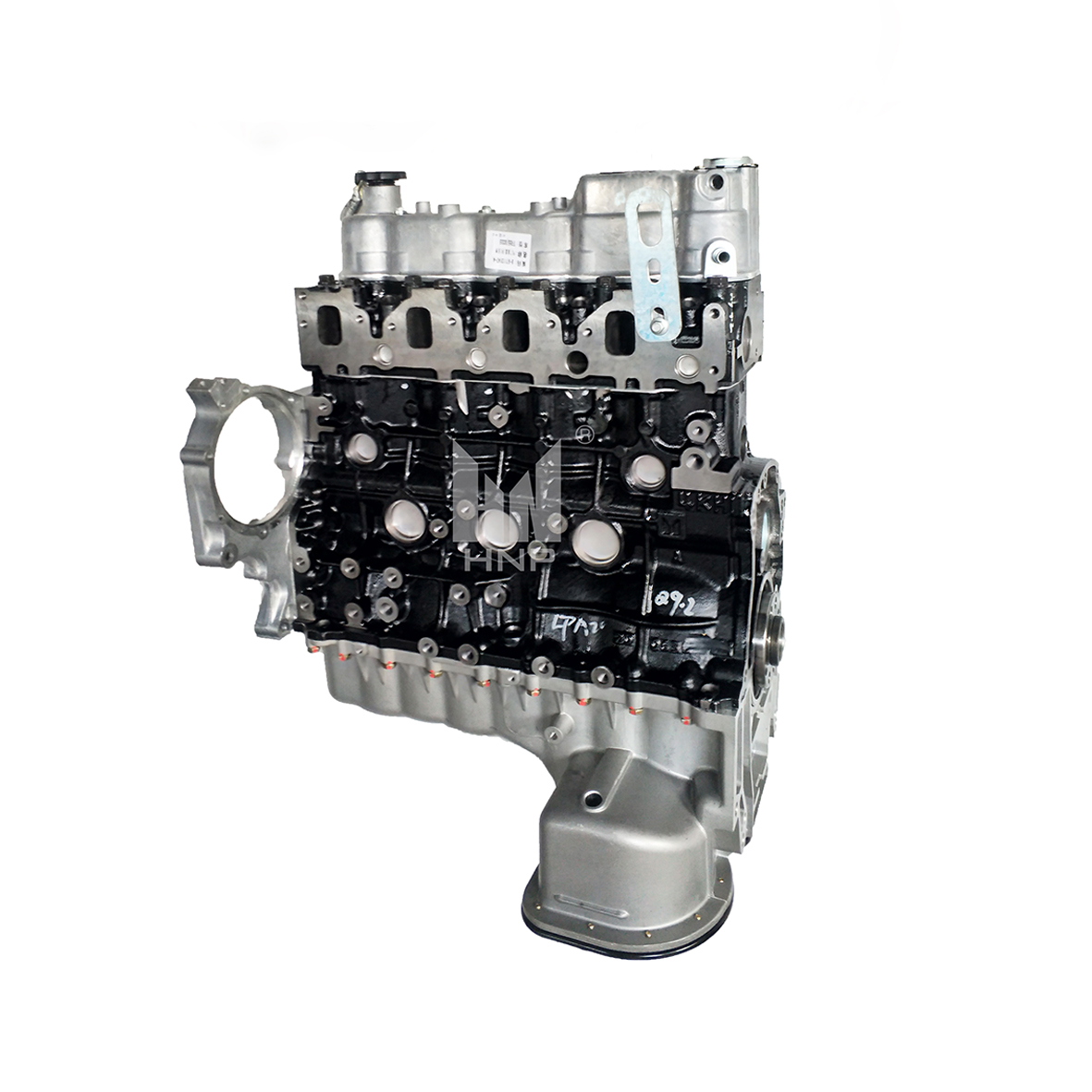

Step 5: Parts Replacement

Pistons are replaced with new ones.

Piston rings, main bearings, and rod bearings are all new.

Sometimes the connecting rods are replaced or reconditioned.

Premium components like forged pistons may be installed for higher durability or performance builds.

Step 6: Reassembly

Assembly takes place in a clean, controlled environment to avoid contamination. Technicians use precision torqueing techniques and special assembly lubricants to ensure long-term reliability.

Step 7: Testing

Some companies spin-test the rotating assembly and pressure-test the block to ensure no leaks or imbalance before the engine is shipped out.

Choosing the Right Remanufactured Short Block Engine

When shopping for a remanufactured short block engine, make sure you do your homework. Key factors to consider:

1. Reputation of the Remanufacturer

Choose companies certified by industry groups like AERA (Automotive Engine Rebuilders Association).

Check customer reviews and third-party ratings.

2. Warranty Coverage

A reputable remanufacturer will offer a strong warranty (12 months minimum, often 36 months for peace of mind).

Be sure to read the fine print — some warranties require professional installation to remain valid.

3. Quality of Replacement Parts

High-quality remanufactured short block engines will use:

- OEM-grade or better pistons, rings, and bearings

- Upgraded materials in critical stress areas

- Thorough balancing of rotating assemblies

4. Matching Your Vehicle’s Needs

Ensure the engine matches your vehicle’s year, model, engine displacement, and performance goals.

Some shops offer custom builds tailored to specific driving styles — from daily commuting to off-road or high-performance driving.

Tips for a Successful Short Block Engine Replacement

Getting the best results from a short block engine replacement depends on careful installation and follow-up:

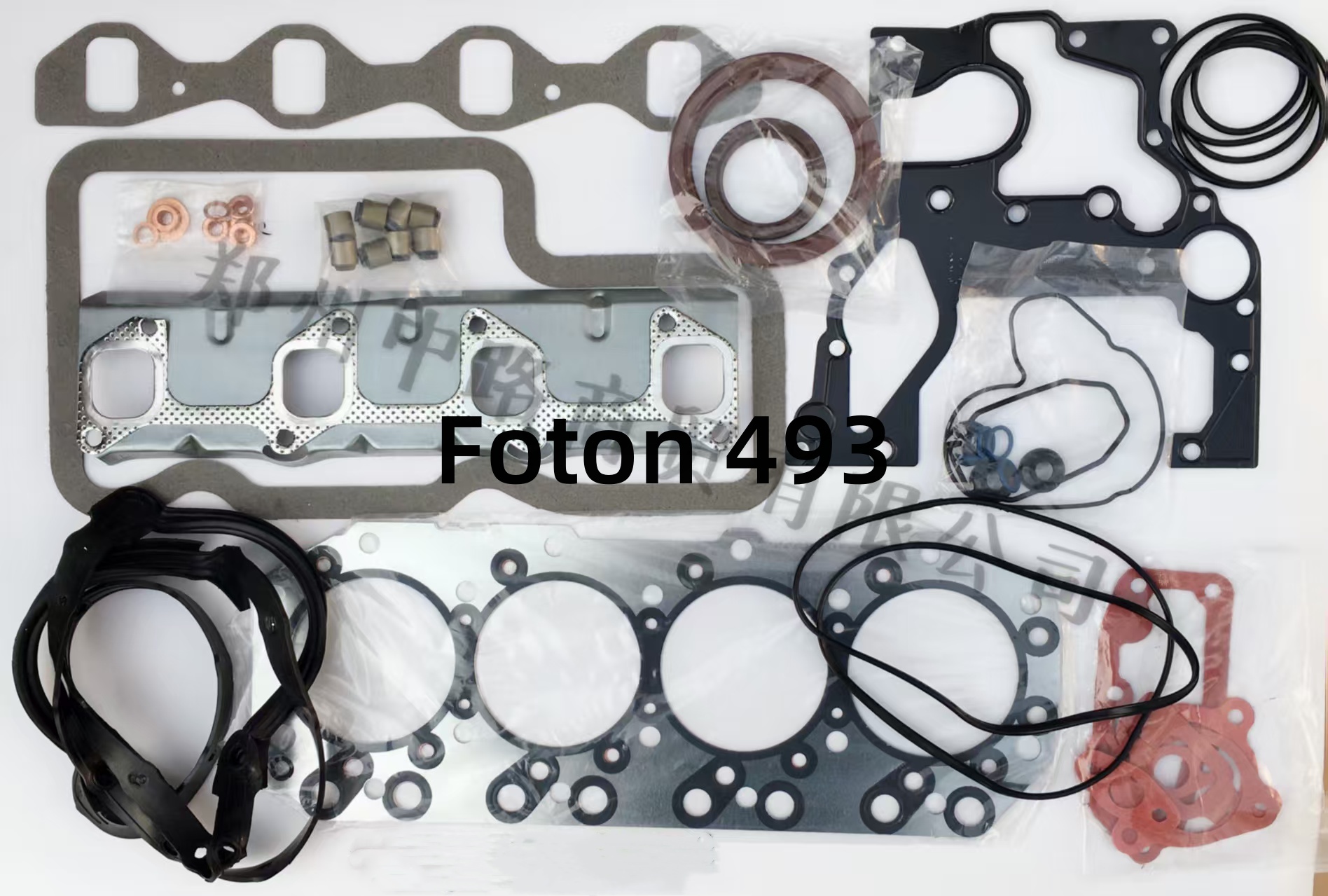

- Replace All Gaskets and Seals: Don't cut corners — bad seals cause leaks and failures.

- Flush Oil and Cooling Systems Thoroughly: Old debris can ruin a new short block.

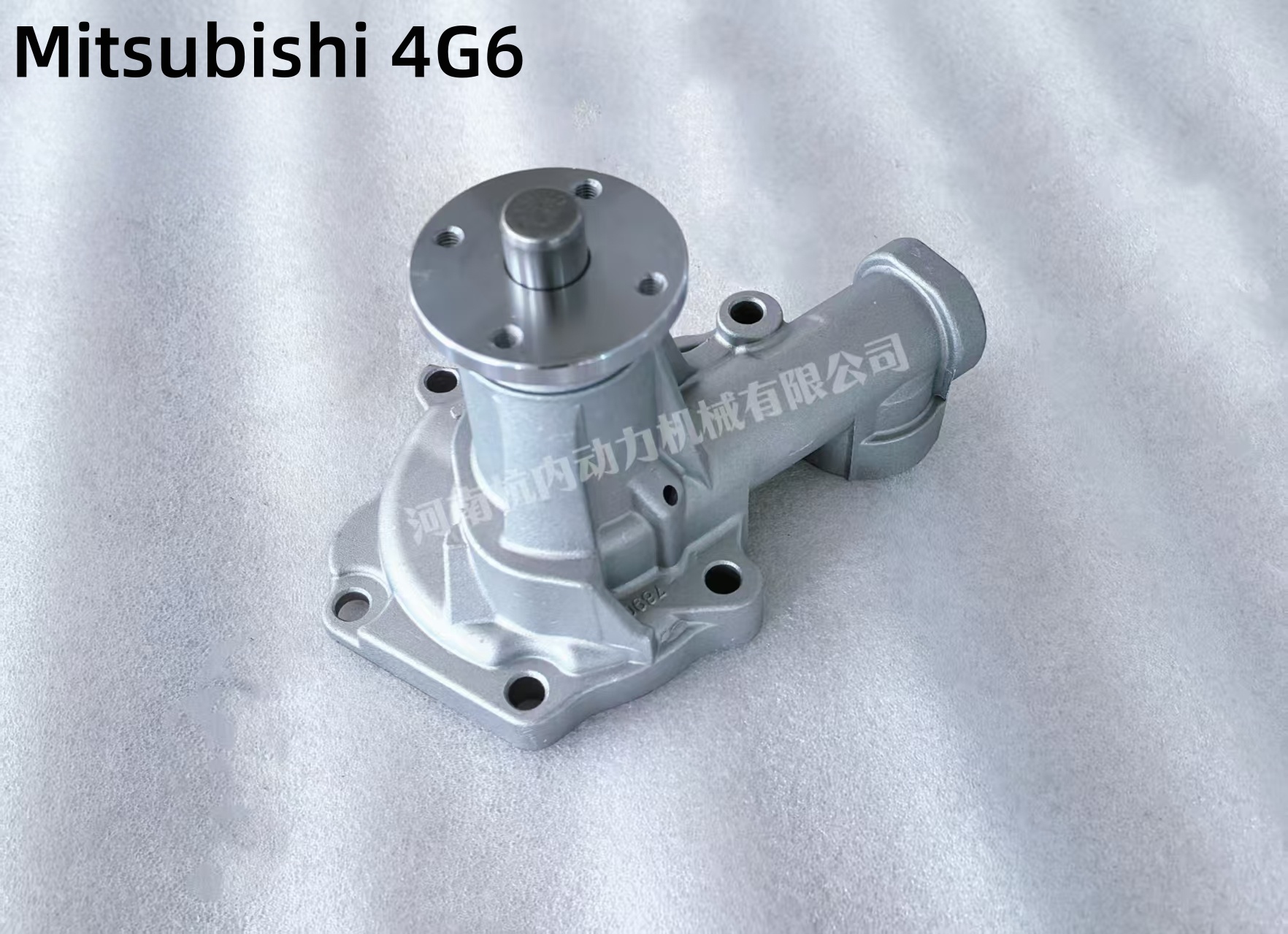

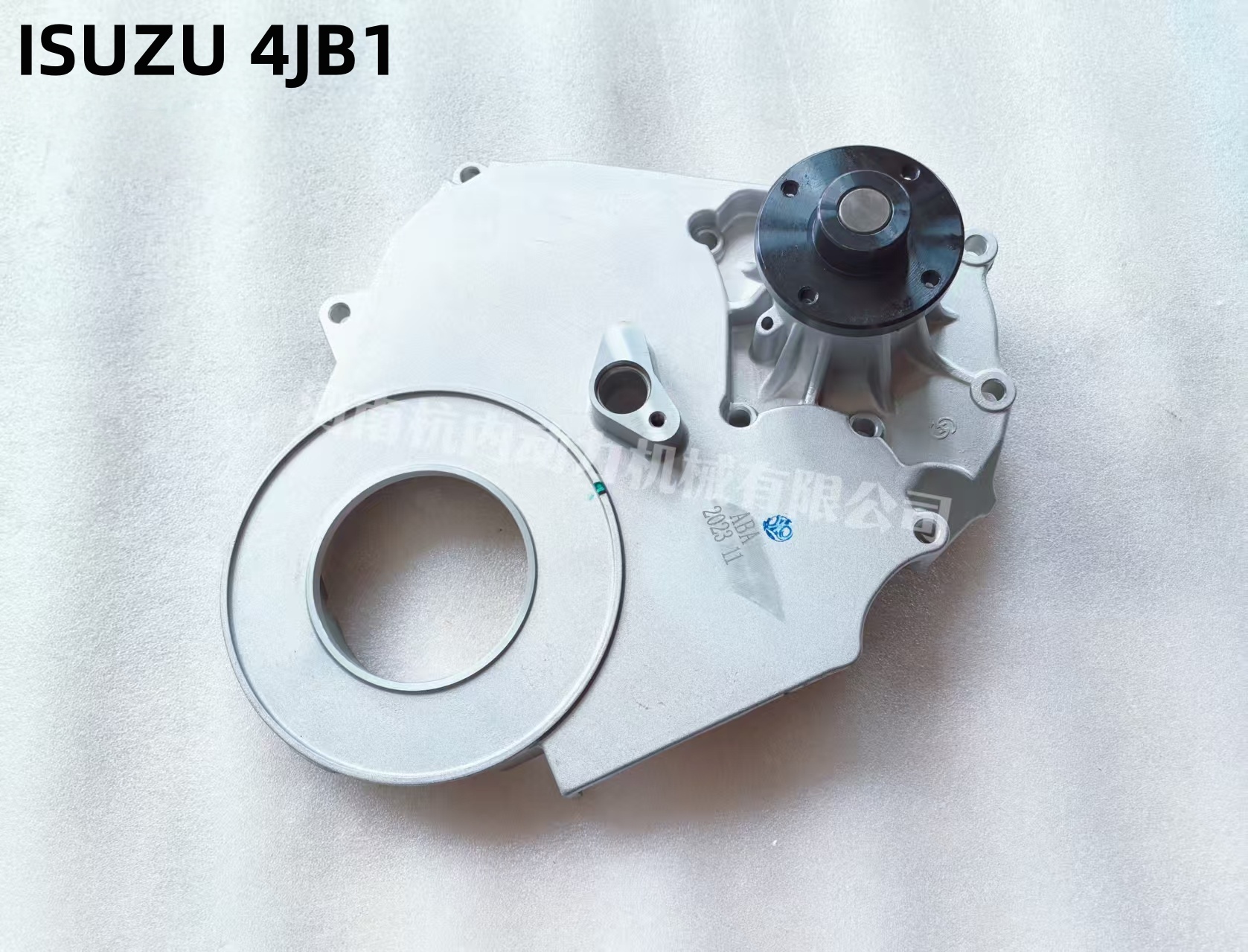

- Inspect Related Components: Replace worn timing chains, water pumps, or cylinder heads if needed.

- Proper Break-In Procedures: Follow recommended break-in protocols, usually involving careful driving for the first 500–1,000 miles and oil changes at 500 miles.

- Use High-Quality Oil: Especially during break-in. Zinc-enhanced oils are often recommended.

Conclusion

Choosing a remanufactured short block engine is not just a smart financial decision — it’s an investment in reliable transportation, sustainability, and long-term vehicle performance. Whether you're facing a catastrophic bottom-end failure, working on a classic restoration, or planning a performance build, a short block engine replacement offers a versatile, cost-effective solution.

By partnering with reputable remanufacturers and following best practices for installation and maintenance, you can enjoy many more years and miles of dependable driving without the steep costs of a brand-new engine.

If your engine has seen better days, don’t give up on your car just yet — explore the potential of a remanufactured short block engine and discover how modern engineering can bring new life to your vehicle.

Read More: 383 Long Block and 383 Stroker Long Block: The Complete Guide

Hot Products

1.jpg)

1.jpg)

.jpg)

1.jpg)

-1.jpg)

.jpg)

-1.jpg)

-1.jpg)

-3.jpg)